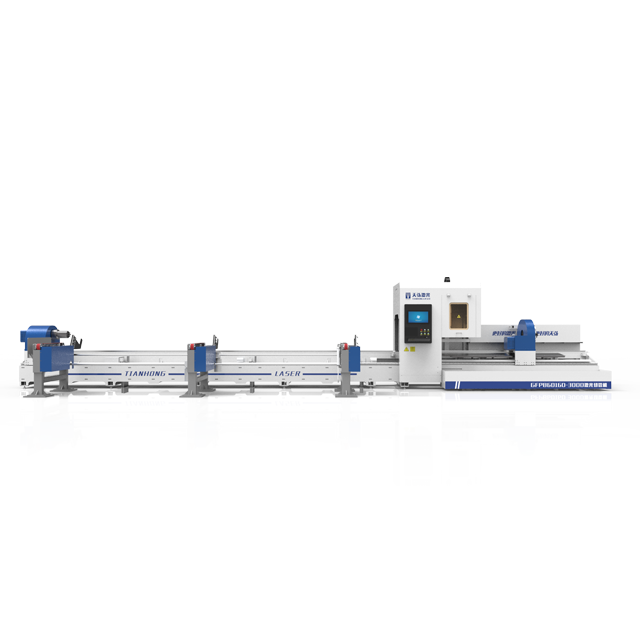

GFPB functional tube laser cutting machines adopt the patented technology of self-centering four-jaw chuck to remove the rope pendulum effect and improve the accuracy of slender tube cutting.

Two chucks are equipped with automatic loading and unloading structure, which not only saves labor cost but also improves production efficiency.

Features of GFPB Functional Tube Laser Cutting Machine

» Middle card & front chuck avoidance cutting, the shortest tail material can reach 70mm;

» The machine tool adopts a high-strength welded bed, professional mechanical analysis, good rigidity and high strength;

» The chuck is driven by a servo motor, equipped with high-precision gears, with high installation accuracy, large transmission torque, small transmission error, and good dynamic characteristics;

» Follow-up support assists cutting to ensure processing accuracy of light and heavy pipes;

» Follow-up support assists blanking to ensure long tube processing accuracy.

Technical Parameters:

Model | GFPA6016D | GFPA6022D | GFPA6032D |

Laser power | 1000-4000W | 1000-4000W | 1000-4000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤400KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-70r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |

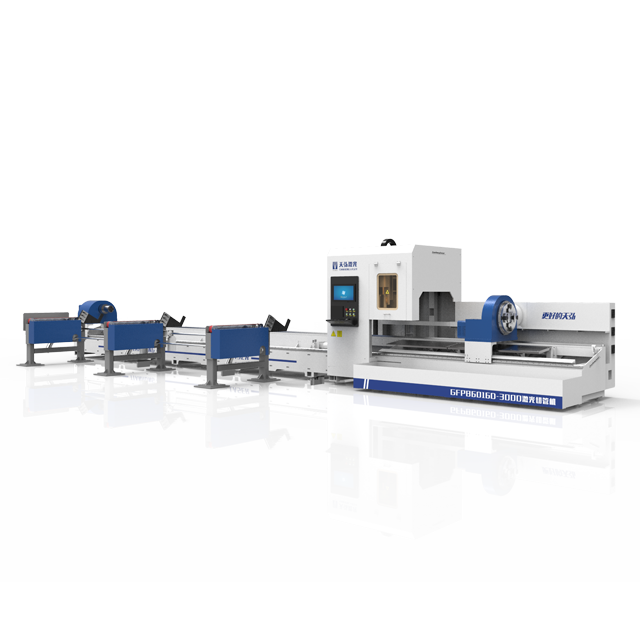

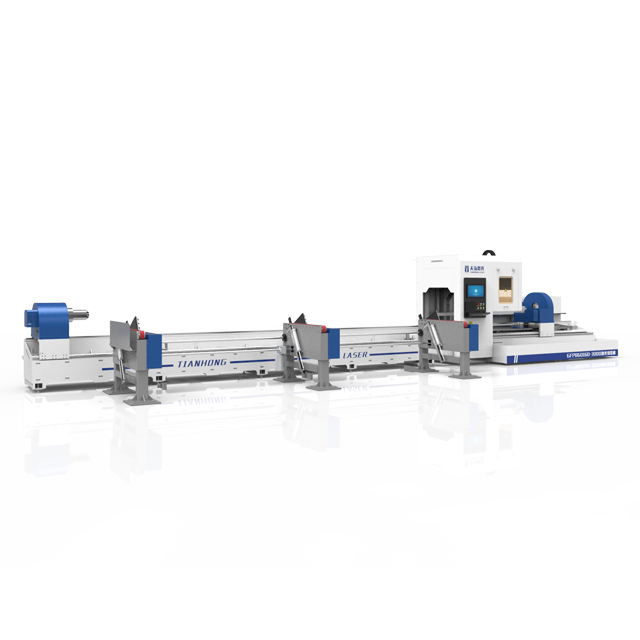

GFPB functional tube laser cutting machines adopt the patented technology of self-centering four-jaw chuck to remove the rope pendulum effect and improve the accuracy of slender tube cutting.

Two chucks are equipped with automatic loading and unloading structure, which not only saves labor cost but also improves production efficiency.

Features of GFPB Functional Tube Laser Cutting Machine

» Middle card & front chuck avoidance cutting, the shortest tail material can reach 70mm;

» The machine tool adopts a high-strength welded bed, professional mechanical analysis, good rigidity and high strength;

» The chuck is driven by a servo motor, equipped with high-precision gears, with high installation accuracy, large transmission torque, small transmission error, and good dynamic characteristics;

» Follow-up support assists cutting to ensure processing accuracy of light and heavy pipes;

» Follow-up support assists blanking to ensure long tube processing accuracy.

Technical Parameters:

Model | GFPA6016D | GFPA6022D | GFPA6032D |

Laser power | 1000-4000W | 1000-4000W | 1000-4000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤400KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-70r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |

Details of GFPB Functional Tube Laser Cutting Machine:

Machine Bed:

1. The overall welded bed has high rigidity and ensures no deformation for a long time;

2. Improve the reinforcement structure through mechanical analysis and multiple product practices;

3. The product is mature and reliable, and the structure is stable.

Gantry Cutting Head Assembly:

1. High-speed screw drive increases processing speed;

2. Closed protection ensures the service life of parts;

3. High rigidity gantry structure ensures processing stability.

Cutting Head Assembly:

1. The one-piece Z-axis body is made of aluminum alloy casting and matched with a precision guide screw transmission module, which has high precision, fast speed and good dynamic response;

2. Z-axis modular design, mature and stable product, reliable structure.

Rear Chuck

1. The repeated positioning accuracy of the chuck is ≤0.15mm, and the rotation accuracy is ≤0.10mm.

2. Level 6 precision, ground gear transmission;

3. Standard clamping range 15-160mm;

4. Customized claws, suitable for cutting short tail materials.

Middle chuck and front chuck

1. The repeated positioning accuracy of the chuck is ≤0.05mm, and the rotation accuracy is ≤0.05mm.

2. Level 6 precision, ground gear transmission;

3. Standard clamping range 15-160mm;

4. Equipped with double-row roller claws to further ensure processing accuracy.

Control System

FUST5000B laser cutting control system is a set of system software for laser cutting pipes, including laser cutting process processing, common layout functions and laser processing control. The main functions include graphics processing, parameter setting, custom cutting process editing, layout, path planning, simulation, and cutting process control.

·Pipe surface height tracking control (follow-up function)

·Rewind function

·Frog jumping function

·High-speed laser pulse function

·Common-edge cutting and other functions

·Round tubes, square tubes, rectangular tubes, angle steel, channel steel, I-beam and other special-shaped tubes

·Support frame follows

Application of GFPB Functional Tube Laser Cutting Machine

Pipe types: round pipes, oval pipes, square pipes, rectangular pipes, special-shaped pipes and other types of pipes;

Materials: carbon steel, stainless steel, alloy steel, aluminum, copper and other materials;

Industry: Various pipe processing industries such as fitness equipment, oil pipelines, engineering machinery, automobile manufacturing, and household appliance manufacturing.

Samples:

Details of GFPB Functional Tube Laser Cutting Machine:

Machine Bed:

1. The overall welded bed has high rigidity and ensures no deformation for a long time;

2. Improve the reinforcement structure through mechanical analysis and multiple product practices;

3. The product is mature and reliable, and the structure is stable.

Gantry Cutting Head Assembly:

1. High-speed screw drive increases processing speed;

2. Closed protection ensures the service life of parts;

3. High rigidity gantry structure ensures processing stability.

Cutting Head Assembly:

1. The one-piece Z-axis body is made of aluminum alloy casting and matched with a precision guide screw transmission module, which has high precision, fast speed and good dynamic response;

2. Z-axis modular design, mature and stable product, reliable structure.

Rear Chuck

1. The repeated positioning accuracy of the chuck is ≤0.15mm, and the rotation accuracy is ≤0.10mm.

2. Level 6 precision, ground gear transmission;

3. Standard clamping range 15-160mm;

4. Customized claws, suitable for cutting short tail materials.

Middle chuck and front chuck

1. The repeated positioning accuracy of the chuck is ≤0.05mm, and the rotation accuracy is ≤0.05mm.

2. Level 6 precision, ground gear transmission;

3. Standard clamping range 15-160mm;

4. Equipped with double-row roller claws to further ensure processing accuracy.

Control System

FUST5000B laser cutting control system is a set of system software for laser cutting pipes, including laser cutting process processing, common layout functions and laser processing control. The main functions include graphics processing, parameter setting, custom cutting process editing, layout, path planning, simulation, and cutting process control.

·Pipe surface height tracking control (follow-up function)

·Rewind function

·Frog jumping function

·High-speed laser pulse function

·Common-edge cutting and other functions

·Round tubes, square tubes, rectangular tubes, angle steel, channel steel, I-beam and other special-shaped tubes

·Support frame follows

Application of GFPB Functional Tube Laser Cutting Machine

Pipe types: round pipes, oval pipes, square pipes, rectangular pipes, special-shaped pipes and other types of pipes;

Materials: carbon steel, stainless steel, alloy steel, aluminum, copper and other materials;

Industry: Various pipe processing industries such as fitness equipment, oil pipelines, engineering machinery, automobile manufacturing, and household appliance manufacturing.

Samples: