100-500W

Aluminum, carbon steel, stainless steel, galvanized sheets

| Availability: | |

|---|---|

Handheld Fiber Laser Cleaning Machine has a lot of superiority compared with the traditional cleaning technology, laser cleaning with non-abrasive, non-contact, non-thermal effect and applicable to a variety of materials and other characteristics of the object, in order to effectively remove the surface of the object rust, oil, film, oxide, paint and other dirt at the same time, there will be no damage to the substrate. Its main mechanism is the object surface dirt absorption of laser energy, or vaporization and volatilization, or instantaneous thermal expansion to overcome the surface of the particle adsorption, so that it is detached from the surface of the object, and then achieve the purpose of cleaning.

» No contact with the surface of the object during laser cleaning. Traditional cleaning methods are often contact cleaning, cleaning the surface of the object has a mechanical force, damage to the surface of the object or cleaning medium attached to the surface of the object to be cleaned, can not be removed, resulting in secondary contamination, the laser cleaning of non-abrasive and non-contact so that these problems are solved.

» No damage to the surface of the object during laser cleaning. Laser cleaning removes all types of contaminants from the surface of various materials to achieve a level of cleanliness that cannot be achieved with conventional cleaning, and can also selectively clean contaminants from the surface of materials without damaging the surface.

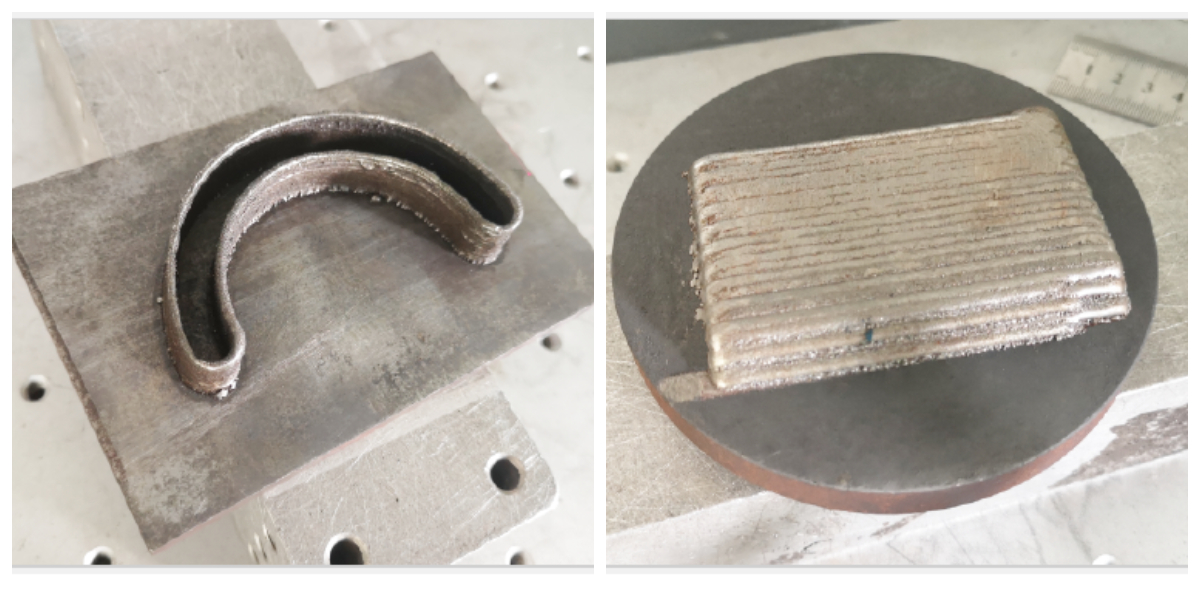

» Laser cleaning for accurate positioning. Use fiber optic transmission to guide the laser, in conjunction with robots and robots, to facilitate the realization of long-distance operation, to facilitate the non-contact laser cleaning of shaped parts, holes, grooves and other nooks and crannies that are difficult to reach by the traditional cleaning methods, which can be used in a number of hazardous places to effectively ensure the safety of personnel.

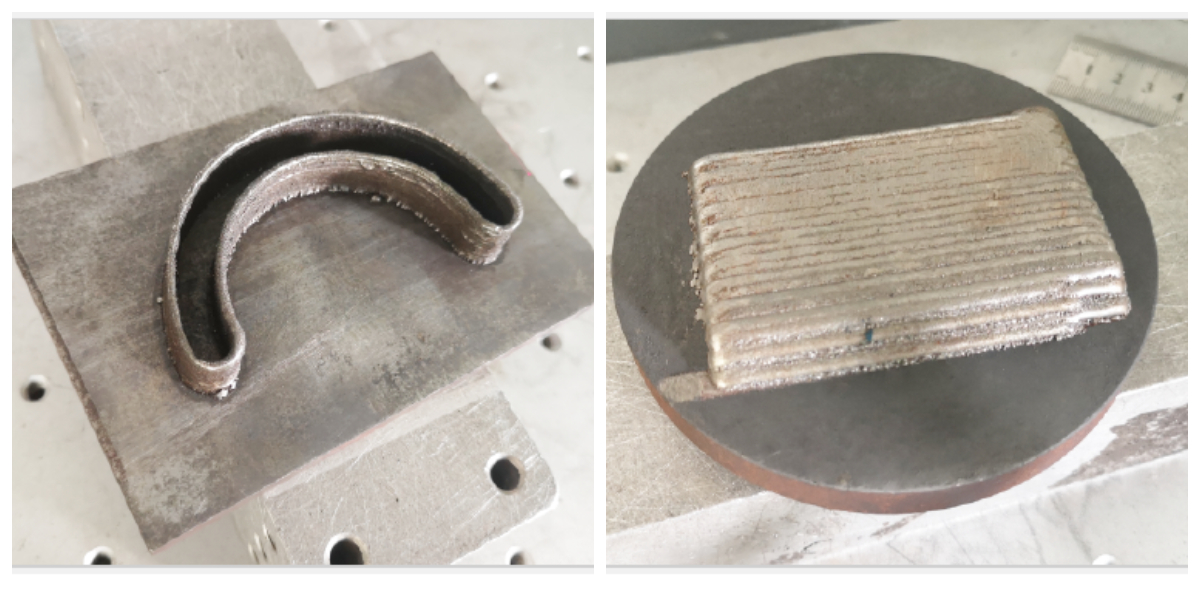

As a laser cleaning technology for industrial production, of course, it can also be used in automated production lines like traditional cleaning technology, as an indispensable process in the industrial production process, such as welding before and after welding seam treatment, localized dirt treatment before spraying paint, and the cleaning of oxides in the production of highly reactive metals, and so on.

Handheld Fiber Laser Cleaning Machine has a lot of superiority compared with the traditional cleaning technology, laser cleaning with non-abrasive, non-contact, non-thermal effect and applicable to a variety of materials and other characteristics of the object, in order to effectively remove the surface of the object rust, oil, film, oxide, paint and other dirt at the same time, there will be no damage to the substrate. Its main mechanism is the object surface dirt absorption of laser energy, or vaporization and volatilization, or instantaneous thermal expansion to overcome the surface of the particle adsorption, so that it is detached from the surface of the object, and then achieve the purpose of cleaning.

» No contact with the surface of the object during laser cleaning. Traditional cleaning methods are often contact cleaning, cleaning the surface of the object has a mechanical force, damage to the surface of the object or cleaning medium attached to the surface of the object to be cleaned, can not be removed, resulting in secondary contamination, the laser cleaning of non-abrasive and non-contact so that these problems are solved.

» No damage to the surface of the object during laser cleaning. Laser cleaning removes all types of contaminants from the surface of various materials to achieve a level of cleanliness that cannot be achieved with conventional cleaning, and can also selectively clean contaminants from the surface of materials without damaging the surface.

» Laser cleaning for accurate positioning. Use fiber optic transmission to guide the laser, in conjunction with robots and robots, to facilitate the realization of long-distance operation, to facilitate the non-contact laser cleaning of shaped parts, holes, grooves and other nooks and crannies that are difficult to reach by the traditional cleaning methods, which can be used in a number of hazardous places to effectively ensure the safety of personnel.

As a laser cleaning technology for industrial production, of course, it can also be used in automated production lines like traditional cleaning technology, as an indispensable process in the industrial production process, such as welding before and after welding seam treatment, localized dirt treatment before spraying paint, and the cleaning of oxides in the production of highly reactive metals, and so on.

| Model | TH-LC-100D-A | TH-LC-200D-A | TH-LC-300D-A | TH-LC-500D-A |

| Laser power | 100W | 200W | 300W | 500W |

| Laser type | Fiber Laser | |||

| Wavelength | 1064nm | |||

| Cooling method | Air cooling/ water cooling | |||

| Water temperature | 18-25℃ | |||

| Cabinet dimension | 575x400x500mm | 610x500x700mm | 640x540x730mm | 850x830x960mm |

| Machine weight | 39.5kg | 52kg | 54kg | 120kg |

| Power consumption | 800W | 1400W | 1600W | 1800W |

| Focus depth | 3mm | 5mm | 10mm | 15mm |

| Scanning width | 2-50mm | |||

| Auxiliary gas | Compressed air / nitrogen | |||

| Air pressure | 0.5-0.8Mpa | |||

| Working environment | 5-40℃ | |||

| Model | TH-LC-100D-A | TH-LC-200D-A | TH-LC-300D-A | TH-LC-500D-A |

| Laser power | 100W | 200W | 300W | 500W |

| Laser type | Fiber Laser | |||

| Wavelength | 1064nm | |||

| Cooling method | Air cooling/ water cooling | |||

| Water temperature | 18-25℃ | |||

| Cabinet dimension | 575x400x500mm | 610x500x700mm | 640x540x730mm | 850x830x960mm |

| Machine weight | 39.5kg | 52kg | 54kg | 120kg |

| Power consumption | 800W | 1400W | 1600W | 1800W |

| Focus depth | 3mm | 5mm | 10mm | 15mm |

| Scanning width | 2-50mm | |||

| Auxiliary gas | Compressed air / nitrogen | |||

| Air pressure | 0.5-0.8Mpa | |||

| Working environment | 5-40℃ | |||