Automotive

At present, in automobile production and manufacturing, body parts can be applied to laser processing( about 50-70%), laser processing technology and equipment has become the development direction of international automobile manufacturing. Tianhong laser provides you with a wide range of processing applications covering body-in-white welding, automotive parts manufacturing, PMS production data management and other aspects of technology, cutting, marking, welding and other laser processes to meet the different needs of enterprises.

Where will lasers be used?

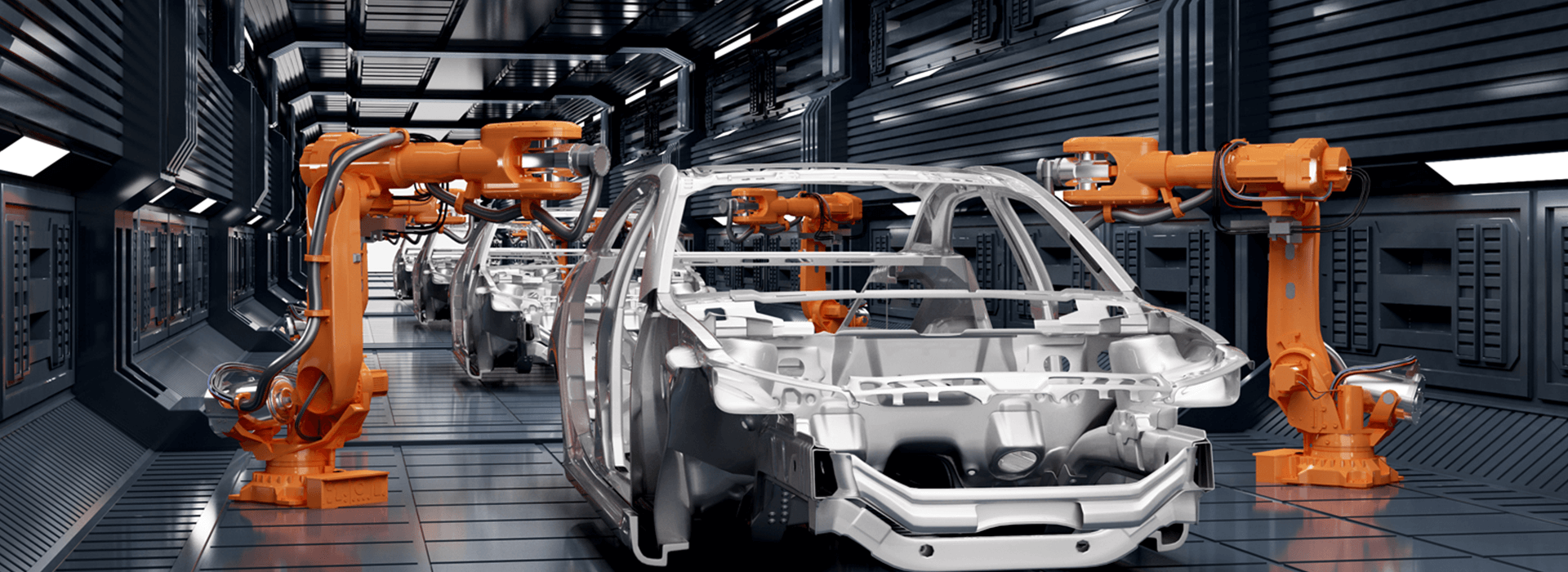

Body-in-White Welding

Flexible laser cutting and welding system for body-inwhite includes top cover laser welding, side enclosure laser welding, rear coverlaser welding, floor and door laser welding. It has features of high precision, high speed, good dynamic performance. It is also equipped with high-performance rotary table, which can meet the high beat requirements of the automotive industry.

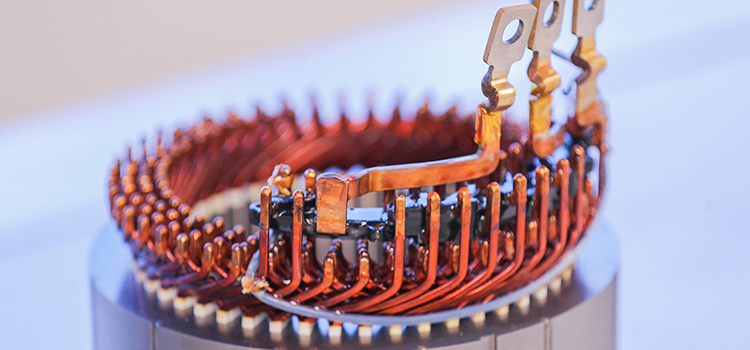

Flat Wire Motor

Tianhong laser provides one-stop solution for flat copper wire laser paint removal and flat wire motor laser welding.

Paint stripping: Adopt a fiber pulse laser with a wavelength of 1070-1080NM, laser power is selected according to the customer's production line beat, this set of mechanism is easy to integrate online and is easy to maintain and adjust.

Welding: High-speed welding by means of vision galvanometer; Rely on vision for precise positioning to ensure accurate welding position; 48 grooves, 8 layers of 192 points to take pictures and welding time is less than or equal to 60 seconds with faster efficiency and higher yield rate.

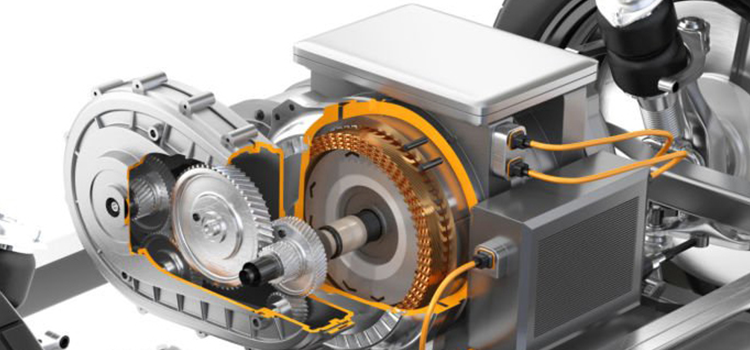

Motor Iron Core

Tianhong laser self-developed motor core laser welding machine is specially designed and manufactured for all kinds of motor stator, rotor iron core multi-channel straight seam and oblique seam welding, which supports welding of a wide range of stator rotors with different outside diameters and stack heights. For the application of motor iron core welding, Tianhong Laser has introduced various types of specialized welding equipment to match the automated production line according to the different process requirements of customers.

Samples

Advantages

Our products are meticulously designed to meet the diverse needs of industries striving for precision, efficiency, and versatility.

Precision and Quality

Our CNC laser machines are engineered with the utmost precision, ensuring that every cut, engrave, or mark is executed with razor-sharp accuracy. This high level of precision results in flawless finishes and reduces the need for post-processing, thereby saving time and resources.

Versatility Across Materials

One of the standout features of our CNC laser cutting machines is their versatility. Capable of handling a wide range of materials—from metals and plastics to wood and glass—our machines empower businesses to explore new creative possibilities and expand their product offerings.

Increased Productivity

Designed for optimum efficiency, our CNC laser cutters significantly reduce production times. With fast cutting speeds and the ability to perform precise cuts in a single pass, our machines streamline the manufacturing process, enabling higher output rates and quicker turnaround times.

Cost Efficiency

ur focus on innovation extends to maximizing cost efficiency for our clients. By reducing material waste and energy consumption, our CNC laser machines offer an eco-friendly and economically advantageous solution.

Customization and Innovation

We understand that each business has unique needs and challenges. That's why we offer customizable solutions tailored to your specific requirements. Whether you're working on pioneering aerospace designs, intricate automotive parts.

Increased Productivity

Choosing our company means more than just acquiring a machine; it's about forming a partnership. We provide comprehensive support and service, ensuring that your investment continues to meet your needs and exceed expectations. From initial consultation and installation to ongoing maintenance and technical assistance, our team of experts is dedicated to your success.

Materials In Laser Applications

FAQ

If you can use design software, it only takes a few hours to master the operation of the laser machine. By conducting some tests, you can understand the suitable speed and power for different materials.

注: 建议上传图片大小690px*460px

注: 建议上传图片大小690px*460px