- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

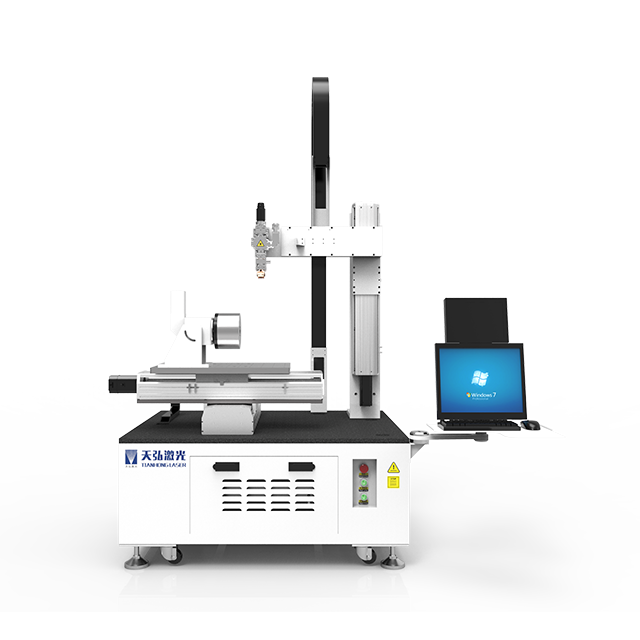

Tianhong Laser provides high efficiency, high quality and low cost laser welding solutions. Suitable for automotive manufacturing, electric motors, new energy lithium batteries, semiconductors, 3C consumer electronics, engineering machinery, chassis cabinets and other industries.

Heat can be reduced to the minimum amount needed, heat-affected zone range is small and deformation caused by heat conduction is minimized.

Stainless steel, carbon steel, aluminum, copper, alloys and other metal materials are applicable.

Power density is high after laser focusing, focal spot diameter is small after high power low-order mode laser focusing.

No tooling wear, heat-affected zone and deformation is very small and can process very small parts.

Can realize any angle welding, can weld complex workpieces and large workpieces with irregular shape.

Automatic high-speed welding, can also realize digital or computer control.

Laser welding machine mainly adopts the high energy density and focusing ability of the laser beam to heat and melt the metal material, thus realizing welding. Laser welding machine can realize various welding methods such as spot welding, butt welding, stack welding, seal welding, etc. It has high depth-to-width ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, flat and beautiful weld. No need to deal with it after welding or only simple treatment, high weld quality, no air holes. It can be accurately controlled with small focusing spot and high positioning accuracy, which is easy to realize automation. This type of welding has the advantages of high precision, fast speed, small deformation, etc. It is widely used in aviation, automobile, electronics and other industries.

Below are some frequently asked questions about laser welding machines, if you have any other questions or need to get a quote for our equipment, please feel free to contact us.

1. Q: Do you offer price discounts or incentives if we purchase a laser welding machine?

A: Depending on the quantity purchased, payment method or partnership, we may offer certain discounts or incentives.

2, Q: How is laser welding machine packaged for safe transportation?

A: We use customized wooden pallet filled with shock-absorbing materials to ensure that the equipment is not damaged during shipping.

3, Q: How do you arrange the transportation of laser welding machine?

A: We work with a number of international logistics companies to ensure that the equipment is delivered safely and quickly to the customer's designated location.

4. Q: What is the warranty period for laser welding machine?

A: We usually offer a one-year or longer warranty, depending on the terms of the contract.

5. Q: How can I repair my equipment if it breaks down?

A: Customers can contact our after-sales service team by phone, e-mail or online service system, we will provide repair support as soon as possible.