- All

- Product Name

- Product Keyword

- Product Model

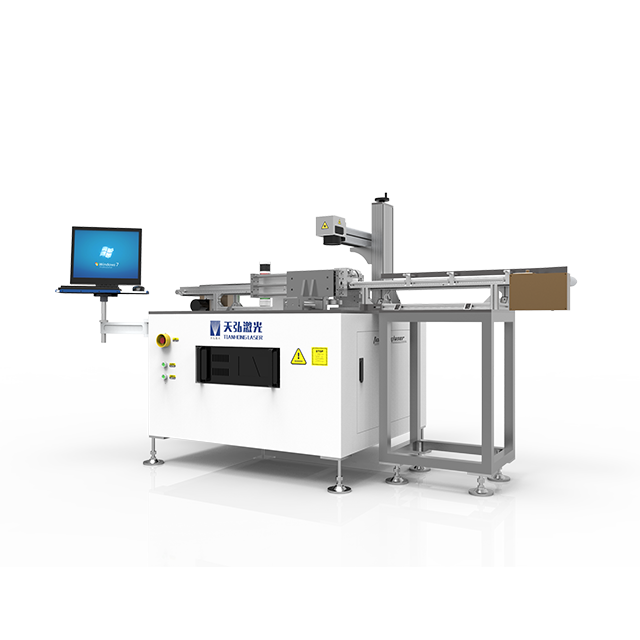

- Product Summary

- Product Description

- Multi Field Search

20W/30W/50W

175x175mm(optional)

Bearing

| Availability: | |

|---|---|

Bearing is a kind of important parts in contemporary mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotary accuracy. And bearing laser marking machine adopts laser beams in a variety of different substances on the surface of the long-lasting marking, marking effect is through the surface layer of material evaporation to reveal the deep material, so as to carve out a beautiful pattern, Logo and text.

» Environmental protection: Laser marking machine does not need to use any chemical substances, will not produce waste gas, waste water and waste residue, so it meets the requirements of environmental protection.

» Wide application range: The laser marking machine can use different laser heads and marking materials, applicable to a variety of materials bearing print marks, such as steel, aluminum, plastic, etc..

» High efficiency: Laser marking machine can complete the printing of bearing marking in a very short time, and each mark is the same high quality standard, greatly improving the production efficiency and production quality.

» High precision: Laser marking machine can be accurately positioned through the computer control, can be marked in the micron level range, the printed mark is very clear and precise, and will not wear the surface and quality of the bearing.

In the bearing industry, bearing laser marking machine is mainly used for bearing marking and identification.Bearing industry is an indispensable part of modern industry, and its bearings are widely used in various mechanical equipment, automobiles, airplanes and other fields. The quality and performance of bearings are directly related to the stability and service life of the whole equipment, so the quality control in the production process is particularly important.

Bearing is a kind of important parts in contemporary mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotary accuracy. And bearing laser marking machine adopts laser beams in a variety of different substances on the surface of the long-lasting marking, marking effect is through the surface layer of material evaporation to reveal the deep material, so as to carve out a beautiful pattern, Logo and text.

» Environmental protection: Laser marking machine does not need to use any chemical substances, will not produce waste gas, waste water and waste residue, so it meets the requirements of environmental protection.

» Wide application range: The laser marking machine can use different laser heads and marking materials, applicable to a variety of materials bearing print marks, such as steel, aluminum, plastic, etc..

» High efficiency: Laser marking machine can complete the printing of bearing marking in a very short time, and each mark is the same high quality standard, greatly improving the production efficiency and production quality.

» High precision: Laser marking machine can be accurately positioned through the computer control, can be marked in the micron level range, the printed mark is very clear and precise, and will not wear the surface and quality of the bearing.

In the bearing industry, bearing laser marking machine is mainly used for bearing marking and identification.Bearing industry is an indispensable part of modern industry, and its bearings are widely used in various mechanical equipment, automobiles, airplanes and other fields. The quality and performance of bearings are directly related to the stability and service life of the whole equipment, so the quality control in the production process is particularly important.

| Model | TH-ZC-FLMS |

| Laser power | 20W/30W/50W |

| Marking range | 175x175mm(optional) |

| Marking method | Single-sided / double-sided marking |

| Bearing outside diameter range | 20-150mm(can be customized) |

| Positioning method | Side V-type IR Positioning / Both Side V-type Positioning Grip Positioning |

| Transmission method | Pipeline method / V-clamp positioning movement method on both sides |

| Marking position | One-sided arc marking at one or more places |

| Electricity requirement | 220V/ single-phase 50HZ/20A |

| Dimension | Can be customized |

| Model | TH-ZC-FLMS |

| Laser power | 20W/30W/50W |

| Marking range | 175x175mm(optional) |

| Marking method | Single-sided / double-sided marking |

| Bearing outside diameter range | 20-150mm(can be customized) |

| Positioning method | Side V-type IR Positioning / Both Side V-type Positioning Grip Positioning |

| Transmission method | Pipeline method / V-clamp positioning movement method on both sides |

| Marking position | One-sided arc marking at one or more places |

| Electricity requirement | 220V/ single-phase 50HZ/20A |

| Dimension | Can be customized |