- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

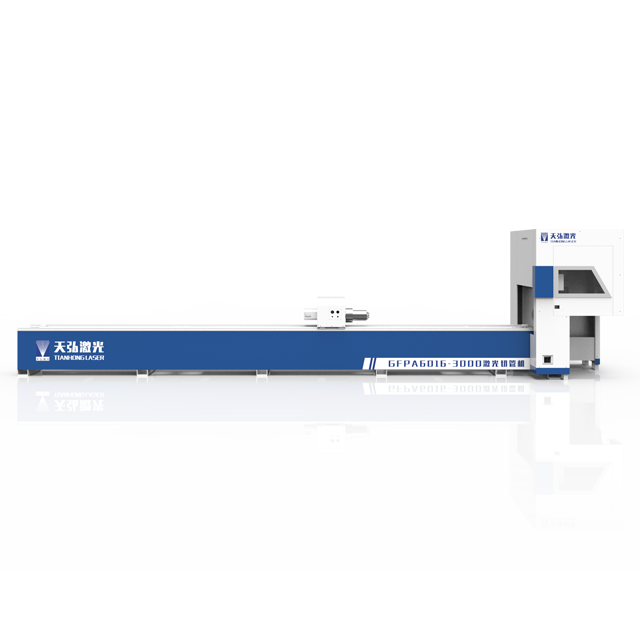

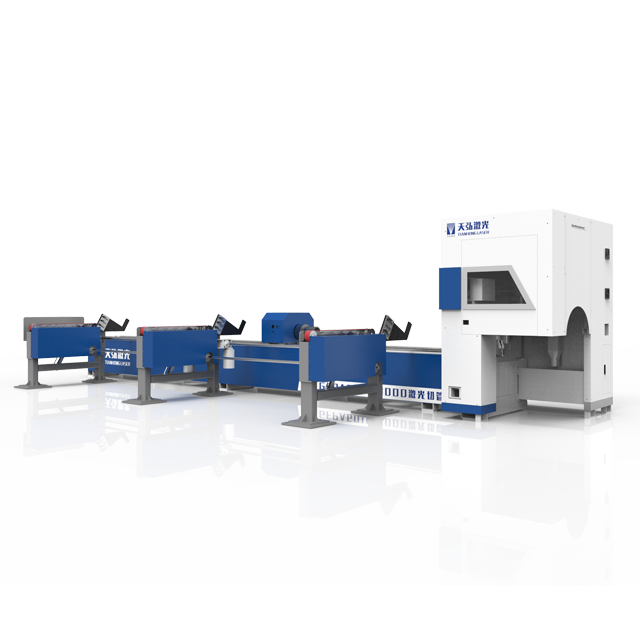

GFPA Professional Tube Laser Cutting Machines are entry-level tube cutting machine models, with automatic pneumatic two-chuck, stable and efficient operation; tube cutting with high speed operation, high efficiency and without interruption.

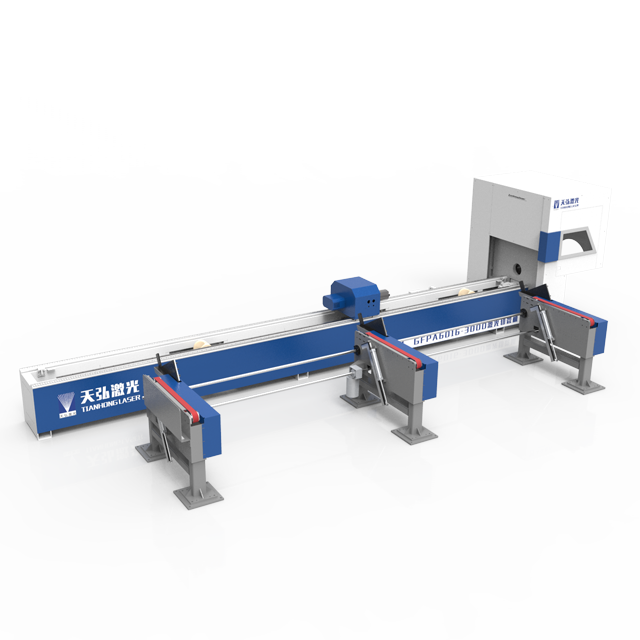

The reducer wheel is used to support the tube when cutting and unloading, which can support the pipe up and down, left and right, thus avoiding the pipe from shaking and ensuring the accuracy.

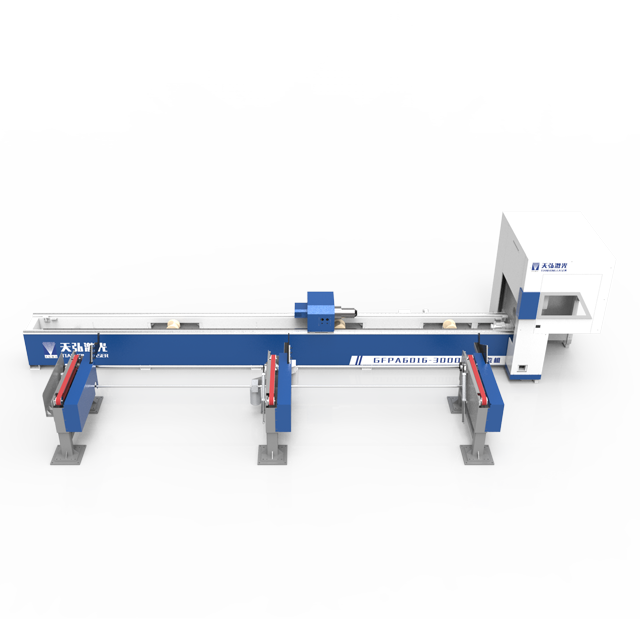

» The front chuck is equipped with double row roller claws to ensure the machining accuracy;

» The machine adopts high strength welding bed, professional mechanical analysis, good rigidity and high strength;

» The chuck is driven by servo motor and equipped with high precision gear, which has high installation accuracy, large transmission torque, small transmission error and good dynamic characteristics;

» The variable diameter wheel supports the auxiliary cutting to ensure the machining accuracy of light and heavy pipe processing;

» A dust cover design is added to the Y-axis to prevent scraps from splashing onto the transmission mechanism during processing, affecting processing accuracy and equipment safety;

» The integrated design of the fixed chuck transmission system ensures the stability of processing accuracy and dust prevention

» The unloading area can be equipped with an optional unloading support device to prevent the long material from swinging and affecting the accuracy.

Pipe types: round pipes, oval pipes, square pipes, rectangular pipes, special-shaped pipes and other types of pipes;

Materials: carbon steel, stainless steel, alloy steel, aluminum, copper and other materials;

Industry: Various pipe processing industries such as fitness equipment, oil pipelines, engineering machinery, automobile manufacturing, and household appliance manufacturing.

Model | GFPA6016 | GFPA6022 | GFPA6032 |

Laser power | 1000-4000W | 1000-4000W | 1000-6000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤170KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-80r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |

GFPA Professional Tube Laser Cutting Machines are entry-level tube cutting machine models, with automatic pneumatic two-chuck, stable and efficient operation; tube cutting with high speed operation, high efficiency and without interruption.

The reducer wheel is used to support the tube when cutting and unloading, which can support the pipe up and down, left and right, thus avoiding the pipe from shaking and ensuring the accuracy.

» The front chuck is equipped with double row roller claws to ensure the machining accuracy;

» The machine adopts high strength welding bed, professional mechanical analysis, good rigidity and high strength;

» The chuck is driven by servo motor and equipped with high precision gear, which has high installation accuracy, large transmission torque, small transmission error and good dynamic characteristics;

» The variable diameter wheel supports the auxiliary cutting to ensure the machining accuracy of light and heavy pipe processing;

» A dust cover design is added to the Y-axis to prevent scraps from splashing onto the transmission mechanism during processing, affecting processing accuracy and equipment safety;

» The integrated design of the fixed chuck transmission system ensures the stability of processing accuracy and dust prevention

» The unloading area can be equipped with an optional unloading support device to prevent the long material from swinging and affecting the accuracy.

Pipe types: round pipes, oval pipes, square pipes, rectangular pipes, special-shaped pipes and other types of pipes;

Materials: carbon steel, stainless steel, alloy steel, aluminum, copper and other materials;

Industry: Various pipe processing industries such as fitness equipment, oil pipelines, engineering machinery, automobile manufacturing, and household appliance manufacturing.

Model | GFPA6016 | GFPA6022 | GFPA6032 |

Laser power | 1000-4000W | 1000-4000W | 1000-6000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤170KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-80r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |