- All

- Product Name

- Product Keyword

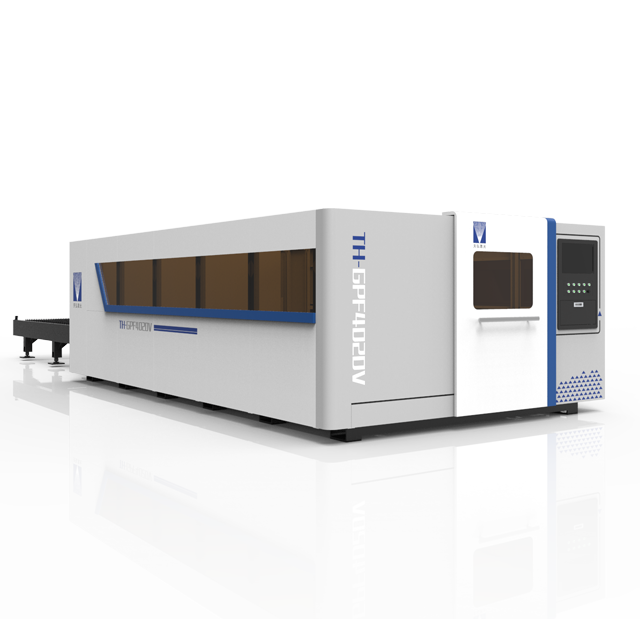

- Product Model

- Product Summary

- Product Description

- Multi Field Search

GPF double exchange laser cutting machine adopts advanced IPG laser source 6000W with international advanced technology. The machine is equipped with high precision pinion and rack, reducer, imported high precision linear guideway, etc. and transmission structure with high efficiency.

It is a high-tech precision product integrated with fiber cutting, precision mechanism, and CNC technology and controlled by Cypcut CNC system. It is capable for cutting and shaping metal material such as carbon steel, stainless steel, aluminum alloy, etc. with features of high speed, high precision, high efficiency, high performance and high cost effective.

Advanced control system and executive structure are adopted on this machine with high precision control and with features of good anti-interference ability and high working reliability, which has gone through advanced technology processing. Meanwhile, it is convenient to operate and easy to maintain with good looking. The design is conformity to ISO international standard. All components and measurement units adopt international unit (SI) standard. It is with reasonable design structure, which has good rigidity, high stability, high reliability and high durability.

Details of GPF Double Exchange Laser Cutting Machine:

Machine Body:

Main body consists of welded bed, crossbeam, loading support, Z axis device, control system, dust removal device, gas & water circuit, and double changing pallets, etc. X, Y and Z axis is driven by AC servo motor to realize cutting head motion with high stability, reliability and high speed. X axis stroke is 2000mm, Y axis stroke is 6000mm. Original packaging imported high precision linear guideway is adopted for X, Y axis, which is equipped with photoelectric sensor. It ensures high precision transmission accuracy and positioning accuracy.

Z axis is not only a single CNC axis to realize interpolation function, but also linkage with X, Y axis transferring to follow-up control, to meet different machining requirements.

Distance between cutting head and sheet metal can be automatically adjusted to effectively guarantee laser cutting quality. It is detected by capacitive sensor in Z axis device. Detected signal is converted to control system, then to control Z axis servo motor to drive cutting head to move.

Machine tool

Bed is equipped with loading roller and backer, which makes it easy to load workpiece and rapid to position. Apart from this, the machine is equipped with dust removal device which ensures unpolluted environment.

Bed adopts welding component. Annealing processing to eliminate interior stress. Procedure as follows:

Welding → annealing → rough machining → vibration aging → half finishing machining → vibration aging → finishing machining.

Above procedure eliminates interior stress caused by welding, which improves machine stability and makes it maintain accuracy for long period.

Cross beam

Cross beam adopts extruded aviation aluminum T6 series with surface anodic treatment, which reduces weight and increases running speed. It improves machine dynamic performance and mechanical performance.

CNC System

Cypcut is a professional sheet laser cutting system software, it contains laser cutting processing technology, regular stock layout function and laser processing control. Main function includes image process, parameter setting, self-defined cut program, layout, path programming, simulation, and cutting processing control.

Application of GPF Double Exchange Laser Cutting Machine

Fiber laser cutting machine is with wide application for metal cutting, electrical switch manufacturing, aerospace, grain machinery, textile machinery, engineering machinery, locomotives, Agricultural and forestry machinery, elevators, special vehicles, household appliance, petroleum machinery, food machinery, etc. industrials and laser cutting job service.

Fiber laser cutting machine is especially capable for cutting various medium and thin sheet metal materials, such as carbon steel, stainless steel, and even capable for cutting aluminum alloy sheet, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum-zinc plate, copper sheet, etc.

GPF double exchange laser cutting machine adopts advanced IPG laser source 6000W with international advanced technology. The machine is equipped with high precision pinion and rack, reducer, imported high precision linear guideway, etc. and transmission structure with high efficiency.

It is a high-tech precision product integrated with fiber cutting, precision mechanism, and CNC technology and controlled by Cypcut CNC system. It is capable for cutting and shaping metal material such as carbon steel, stainless steel, aluminum alloy, etc. with features of high speed, high precision, high efficiency, high performance and high cost effective.

Advanced control system and executive structure are adopted on this machine with high precision control and with features of good anti-interference ability and high working reliability, which has gone through advanced technology processing. Meanwhile, it is convenient to operate and easy to maintain with good looking. The design is conformity to ISO international standard. All components and measurement units adopt international unit (SI) standard. It is with reasonable design structure, which has good rigidity, high stability, high reliability and high durability.

Details of GPF Double Exchange Laser Cutting Machine:

Machine Body:

Main body consists of welded bed, crossbeam, loading support, Z axis device, control system, dust removal device, gas & water circuit, and double changing pallets, etc. X, Y and Z axis is driven by AC servo motor to realize cutting head motion with high stability, reliability and high speed. X axis stroke is 2000mm, Y axis stroke is 6000mm. Original packaging imported high precision linear guideway is adopted for X, Y axis, which is equipped with photoelectric sensor. It ensures high precision transmission accuracy and positioning accuracy.

Z axis is not only a single CNC axis to realize interpolation function, but also linkage with X, Y axis transferring to follow-up control, to meet different machining requirements.

Distance between cutting head and sheet metal can be automatically adjusted to effectively guarantee laser cutting quality. It is detected by capacitive sensor in Z axis device. Detected signal is converted to control system, then to control Z axis servo motor to drive cutting head to move.

Machine tool

Bed is equipped with loading roller and backer, which makes it easy to load workpiece and rapid to position. Apart from this, the machine is equipped with dust removal device which ensures unpolluted environment.

Bed adopts welding component. Annealing processing to eliminate interior stress. Procedure as follows:

Welding → annealing → rough machining → vibration aging → half finishing machining → vibration aging → finishing machining.

Above procedure eliminates interior stress caused by welding, which improves machine stability and makes it maintain accuracy for long period.

Cross beam

Cross beam adopts extruded aviation aluminum T6 series with surface anodic treatment, which reduces weight and increases running speed. It improves machine dynamic performance and mechanical performance.

CNC System

Cypcut is a professional sheet laser cutting system software, it contains laser cutting processing technology, regular stock layout function and laser processing control. Main function includes image process, parameter setting, self-defined cut program, layout, path programming, simulation, and cutting processing control.

Application of GPF Double Exchange Laser Cutting Machine

Fiber laser cutting machine is with wide application for metal cutting, electrical switch manufacturing, aerospace, grain machinery, textile machinery, engineering machinery, locomotives, Agricultural and forestry machinery, elevators, special vehicles, household appliance, petroleum machinery, food machinery, etc. industrials and laser cutting job service.

Fiber laser cutting machine is especially capable for cutting various medium and thin sheet metal materials, such as carbon steel, stainless steel, and even capable for cutting aluminum alloy sheet, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum-zinc plate, copper sheet, etc.

Advantages of GPF Double Exchange Laser Cutting Machine

» High photoelectrical conversion efficiency and low power consumption;

» High speed cutting and drilling;

» Light path maintenance free;

» High cutting efficiency;

» Aluminum crossbeam with light weight.

Technical Parameters:

Model | TH-GPF3015V | TH-GPF4020V | TH-GPF6020V | TH-GPF6025 | TH-GPF8025 | TH-GPF12025 |

Laser power | 1000-6000W | 1000-6000W | 1500-6000W | 6000-30000W | 6000-30000W | 12000-30000W |

Z-axis path | 250mm | 250mm | 250mm | 250mm | 350mm | 350mm |

Positioning accuracy | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m | ±0.03mm/m | ±0.03mm/m |

Repetition positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

Processing format | 3000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2500mm | 8000*2500mm | 12000*2500mm |

Advantages of GPF Double Exchange Laser Cutting Machine

» High photoelectrical conversion efficiency and low power consumption;

» High speed cutting and drilling;

» Light path maintenance free;

» High cutting efficiency;

» Aluminum crossbeam with light weight.

Technical Parameters:

Model | TH-GPF3015V | TH-GPF4020V | TH-GPF6020V | TH-GPF6025 | TH-GPF8025 | TH-GPF12025 |

Laser power | 1000-6000W | 1000-6000W | 1500-6000W | 6000-30000W | 6000-30000W | 12000-30000W |

Z-axis path | 250mm | 250mm | 250mm | 250mm | 350mm | 350mm |

Positioning accuracy | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m | ±0.03mm/m | ±0.03mm/m |

Repetition positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

Processing format | 3000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2500mm | 8000*2500mm | 12000*2500mm |