- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

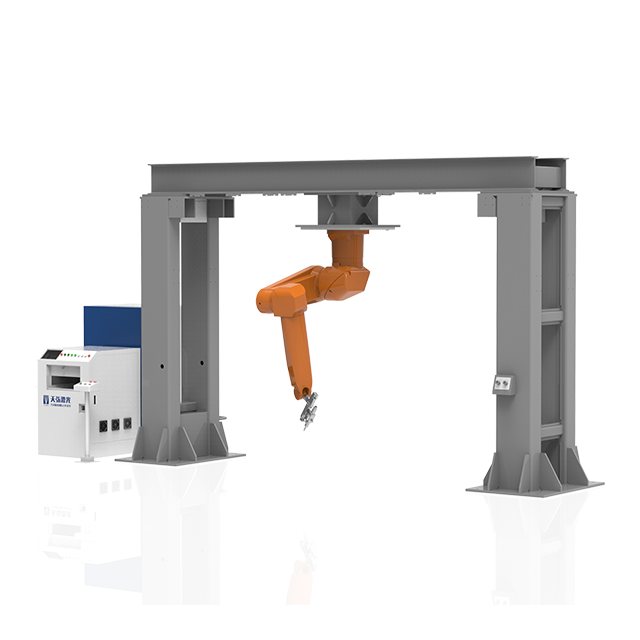

Advantages of Three-dimensional Gantry Laser Cutting Machine

The cutting speed is fast, twice that of similar products. Typical parameters are a 500W laser for 0.5mm thick carbon steel, and a linear cutting speed of up to 10 meters/minute.

High cutting accuracy. The system's repeatable positioning accuracy is as high as ±0.10mm, which can fully meet the needs of the automotive sheet metal covering industry.

It can cut small circles with a diameter less than 10mm. The cutting effect is smooth and beautiful, and there is no deformation or burr under visual inspection. The cutting time of a single small circle can be controlled within 2 seconds.

With the optional manipulator with an arm length of 2.05 meters, in addition to achieving a hemispherical three-dimensional processing area with a diameter of up to 3 meters, it can also achieve two-dimensional plane cutting of 3 meters × 1.5 meters. It realizes the integration of 2D and 3D cutting into one, cuts materials on standard blanks, and combines it with the 2D software developed by our company for free delivery. It has functions such as nesting and path optimization, and is truly suitable for the initial investment in the sheet metal industry.

Choose offline programming software according to actual needs. It can read digital models in vda, igs, x_t, sldprt, prt, stp, ipt, par and other formats exported by UG, SOLIDWORK and other three-dimensional drawing software, and directly generate cutting after modification. Trajectory, instead of manual teaching, is simple and easy to use.

Industrial control concept, modular design, the protection level of the whole system is IP55, and the protection level of the robot is as high as IP65. The system has high integration, few faults, resistance to shock and vibration, dust resistance, and no need for optical adjustment or maintenance. It is truly suitable for Applications in industrial processing fields.

Technical Parameters:

Model | TH-RCF2010S |

Laser power | 500W-1500W |

Working range | 2400mm(Depend on the specific stamping parts) |

Robot max. loading | 20 KG |

Robot rated loading | 20 KG |

Robot track accuracy | ±0.10mm |

Robot repetition accuracy | ±0.06mm |

Robot weight | 380 KG |

Installation way | Overhead type |

Processing material thickness | 0.5 mm- 4mm(carbon steel) |

Cutting speed | 1mm、8m/minute; 2mm、4m/minute; 3mm、2m/minute; 4mm、1.2m/minute; |

Cooling way | water cooling |

Advantages of Three-dimensional Gantry Laser Cutting Machine

The cutting speed is fast, twice that of similar products. Typical parameters are a 500W laser for 0.5mm thick carbon steel, and a linear cutting speed of up to 10 meters/minute.

High cutting accuracy. The system's repeatable positioning accuracy is as high as ±0.10mm, which can fully meet the needs of the automotive sheet metal covering industry.

It can cut small circles with a diameter less than 10mm. The cutting effect is smooth and beautiful, and there is no deformation or burr under visual inspection. The cutting time of a single small circle can be controlled within 2 seconds.

With the optional manipulator with an arm length of 2.05 meters, in addition to achieving a hemispherical three-dimensional processing area with a diameter of up to 3 meters, it can also achieve two-dimensional plane cutting of 3 meters × 1.5 meters. It realizes the integration of 2D and 3D cutting into one, cuts materials on standard blanks, and combines it with the 2D software developed by our company for free delivery. It has functions such as nesting and path optimization, and is truly suitable for the initial investment in the sheet metal industry.

Choose offline programming software according to actual needs. It can read digital models in vda, igs, x_t, sldprt, prt, stp, ipt, par and other formats exported by UG, SOLIDWORK and other three-dimensional drawing software, and directly generate cutting after modification. Trajectory, instead of manual teaching, is simple and easy to use.

Industrial control concept, modular design, the protection level of the whole system is IP55, and the protection level of the robot is as high as IP65. The system has high integration, few faults, resistance to shock and vibration, dust resistance, and no need for optical adjustment or maintenance. It is truly suitable for Applications in industrial processing fields.

Technical Parameters:

Model | TH-RCF2010S |

Laser power | 500W-1500W |

Working range | 2400mm(Depend on the specific stamping parts) |

Robot max. loading | 20 KG |

Robot rated loading | 20 KG |

Robot track accuracy | ±0.10mm |

Robot repetition accuracy | ±0.06mm |

Robot weight | 380 KG |

Installation way | Overhead type |

Processing material thickness | 0.5 mm- 4mm(carbon steel) |

Cutting speed | 1mm、8m/minute; 2mm、4m/minute; 3mm、2m/minute; 4mm、1.2m/minute; |

Cooling way | water cooling |