- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

50W-100W

Namplate

| Availability: | |

|---|---|

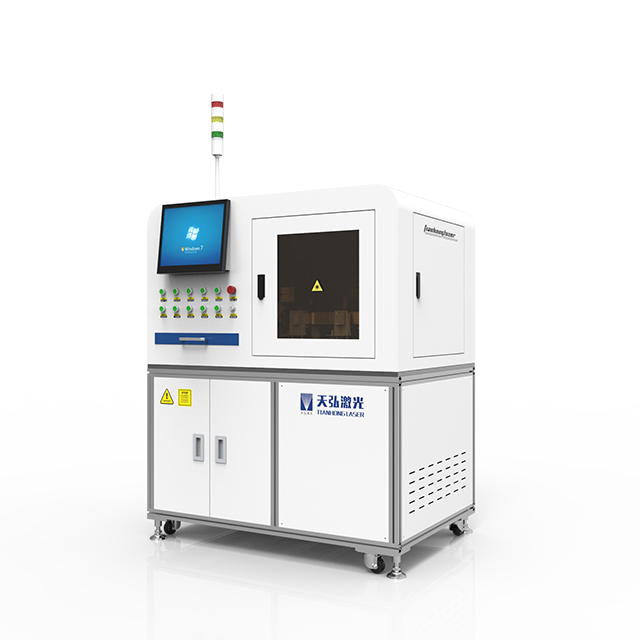

This Enclosed Desktop Nameplate Laser Marking Machine delivers power and performance in a compact size to help you work in the non-horizontal applications. Fiber laser long time service life up to 100000 hours, support metal and most of non-metal material marking with non-fade marks and picture as you need.

» Great processing efficiency, marking speed ten times or more faster than the typical engraving models.

» Stable laser power output and great marking clarity. No restrictions on the operating system, simple to use and program, totally closed optical route that requires no maintenance;

» Just electricity, no other consumables, equipment life;

» Low noise, suitable for use in an office setting, low power consumption;

» Ultra-high fineness.

» In contrast to conventional models, laser marking eliminates the necessity for mechanical contact with the nameplate. High level of automation and simple to understand operation

» Range size is scalable and alignable with various nameplate criteria. precise printing position and absolute positioning setup

Enclosed Desktop Nameplate Laser Marking Machine is the primary application for Automatic Laser Marking Machines.Metal nameplates are attached to products and serve as a means of communicating the manufacturer's brand and other information to consumers. They typically contain the following information: the product name, specifications, date of production, alloy, copper, aluminum, and other common metals; examples of these include nameplates for industrial equipment units, home appliances, office equipment, automobiles, and electronic products.

This Enclosed Desktop Nameplate Laser Marking Machine delivers power and performance in a compact size to help you work in the non-horizontal applications. Fiber laser long time service life up to 100000 hours, support metal and most of non-metal material marking with non-fade marks and picture as you need.

» Great processing efficiency, marking speed ten times or more faster than the typical engraving models.

» Stable laser power output and great marking clarity. No restrictions on the operating system, simple to use and program, totally closed optical route that requires no maintenance;

» Just electricity, no other consumables, equipment life;

» Low noise, suitable for use in an office setting, low power consumption;

» Ultra-high fineness.

» In contrast to conventional models, laser marking eliminates the necessity for mechanical contact with the nameplate. High level of automation and simple to understand operation

» Range size is scalable and alignable with various nameplate criteria. precise printing position and absolute positioning setup

Enclosed Desktop Nameplate Laser Marking Machine is the primary application for Automatic Laser Marking Machines.Metal nameplates are attached to products and serve as a means of communicating the manufacturer's brand and other information to consumers. They typically contain the following information: the product name, specifications, date of production, alloy, copper, aluminum, and other common metals; examples of these include nameplates for industrial equipment units, home appliances, office equipment, automobiles, and electronic products.

Model | TH-MP-FLMS-50 | TH-MP-FLMS-100 |

| Laser source | Imported IPG fiber laser | |

| Wavelength | 1064nm | |

Positioning method | Fixture shape positioning | Fixture shape positioning |

Auto focus method | Ranging sensor positioning | Ranging sensor positioning |

Processing nameplate stations number | Multi-station | Multi-station |

Laser power | 50W | 100W |

Unloading method | Multi-station receiving and unloading | Multi-station receiving and unloading |

| Electricity requirements | 220V/ single-phase 50HZ/20A | |

Dimension | 1300x900x1600 mm | 2400x1050x1800 mm |

Special function | - | Grind and remove metal chips |

Model | TH-MP-FLMS-50 | TH-MP-FLMS-100 |

| Laser source | Imported IPG fiber laser | |

| Wavelength | 1064nm | |

Positioning method | Fixture shape positioning | Fixture shape positioning |

Auto focus method | Ranging sensor positioning | Ranging sensor positioning |

Processing nameplate stations number | Multi-station | Multi-station |

Laser power | 50W | 100W |

Unloading method | Multi-station receiving and unloading | Multi-station receiving and unloading |

| Electricity requirements | 220V/ single-phase 50HZ/20A | |

Dimension | 1300x900x1600 mm | 2400x1050x1800 mm |

Special function | - | Grind and remove metal chips |