- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

1000W-4000W

6016-6032

carbon steel, stainless steel, alloy steel, aluminum, copper, etc

| Availability: | |

|---|---|

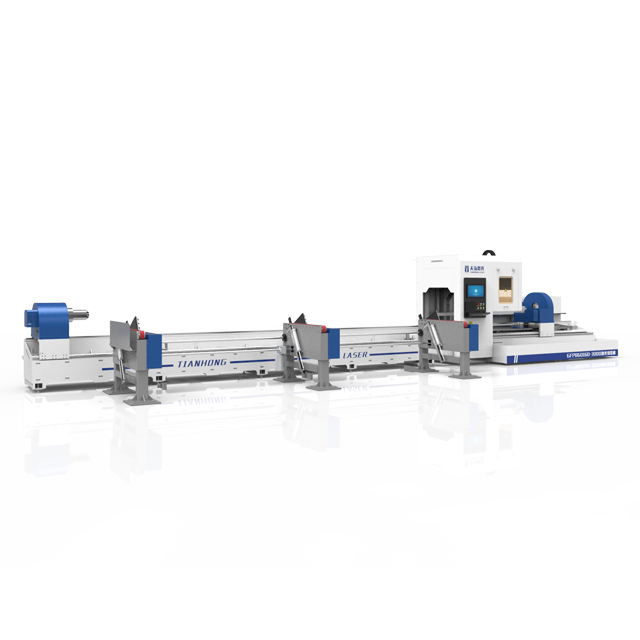

The 6 Meters CNC Fiber Pipe Metal Tube Laser Cutting Machine addresses key challenges in the pipe processing industry, such as inefficient cutting, material wastage, and labor-intensive operations. Traditional methods often struggle with precision and speed, but this laser cutting machine offers a solution by automating the process, ensuring clean, precise cuts at a faster rate, and reducing material waste.

With its advanced CNC technology, this machine allows for seamless cutting of various metals and materials, providing flexibility for custom pipe cutting operations. The integration of computer-aided design (CAD) software enables easy programming and ensures high accuracy in the cutting process.

The system is designed to handle a wide range of material types, thicknesses, and geometries, offering great versatility in tube cutting. The machine’s ability to work with different materials streamlines production, making it ideal for industries such as construction, automotive, and manufacturing.Equipped with an automated cutting system, the machine optimizes cutting speed and efficiency, significantly reducing manual labor. This leads to a faster turnaround time for projects and improved productivity on the manufacturing floor.

Additionally, the database in the operating system stores crucial information about material specifications, ensuring the correct parameters are applied for each cutting job. This feature helps maintain consistency and quality in production, leading to fewer errors and more reliable outcomes.

High precision and efficiency: The CNC Fiber Pipe Metal Tube Laser Cutting Machine provides precise cuts with high centering accuracy, ensuring minimal material wastage and consistent results across various tube sizes and materials.

Flexible laser transmission and compact design: The machine uses fiber laser transmission for high flexibility in cutting. Its compact cutting head structure eliminates the need for reflective lenses, making it virtually maintenance-free and enhancing its durability.

Powerful cutting capabilities: Equipped with a four-claw self-centering chuck, the machine can easily cut various shapes, including square, round, rectangular pipes, and other special-shaped tubes, offering versatility for different manufacturing needs.

Customizable pipe size: The machine can handle pipes with customizable diameters and lengths, with standard round pipe sizes ranging from Φ30 to 160mm and a maximum length of 6000mm, accommodating a wide range of pipe dimensions.

High cost performance: Offering low operational and maintenance costs, the machine provides excellent value for money. Its efficient design and minimal maintenance requirements reduce long-term expenses for businesses.

Simple and user-friendly operation: The cutting system is easy to operate, even for new users. It includes real-time feedback mechanisms to monitor the cutting process, ensuring smooth and efficient operations throughout the manufacturing cycle.

Round, oval, and square pipe cutting

The CNC Fiber Pipe Laser Cutting Machine is capable of cutting round, oval, square, and rectangular pipes, as well as other shaped pipes, offering flexibility for various pipe processing needs.

Variety of materials

It efficiently cuts different materials, including carbon steel, stainless steel, alloy steel, aluminum, and copper, making it suitable for a wide range of industrial applications.

Fitness equipment

This machine is commonly used in the production of fitness equipment, where precise pipe cutting is needed for items like frames, handlebars, and structural supports.

Oil pipelines

It plays a crucial role in the oil pipeline industry, providing high-precision cuts for pipes used in the transport and distribution of oil and gas.

Construction machinery

The machine is utilized in the construction machinery industry for cutting pipes that are part of heavy machinery, ensuring durability and precise dimensions for safety and functionality.

Automobile manufacturing

In the automotive industry, the machine cuts pipes for various components, such as exhaust systems, frames, and engine parts, contributing to production efficiency.

Household appliances

It is also used in household appliance production for cutting pipes and metal components, ensuring high-quality and accurately sized parts for product assembly.

General pipe processing

The machine is a valuable tool in any industry requiring precision pipe cutting, enhancing efficiency and quality in mass production and custom orders.

The 6 Meters CNC Fiber Pipe Metal Tube Laser Cutting Machine addresses key challenges in the pipe processing industry, such as inefficient cutting, material wastage, and labor-intensive operations. Traditional methods often struggle with precision and speed, but this laser cutting machine offers a solution by automating the process, ensuring clean, precise cuts at a faster rate, and reducing material waste.

With its advanced CNC technology, this machine allows for seamless cutting of various metals and materials, providing flexibility for custom pipe cutting operations. The integration of computer-aided design (CAD) software enables easy programming and ensures high accuracy in the cutting process.

The system is designed to handle a wide range of material types, thicknesses, and geometries, offering great versatility in tube cutting. The machine’s ability to work with different materials streamlines production, making it ideal for industries such as construction, automotive, and manufacturing.Equipped with an automated cutting system, the machine optimizes cutting speed and efficiency, significantly reducing manual labor. This leads to a faster turnaround time for projects and improved productivity on the manufacturing floor.

Additionally, the database in the operating system stores crucial information about material specifications, ensuring the correct parameters are applied for each cutting job. This feature helps maintain consistency and quality in production, leading to fewer errors and more reliable outcomes.

High precision and efficiency: The CNC Fiber Pipe Metal Tube Laser Cutting Machine provides precise cuts with high centering accuracy, ensuring minimal material wastage and consistent results across various tube sizes and materials.

Flexible laser transmission and compact design: The machine uses fiber laser transmission for high flexibility in cutting. Its compact cutting head structure eliminates the need for reflective lenses, making it virtually maintenance-free and enhancing its durability.

Powerful cutting capabilities: Equipped with a four-claw self-centering chuck, the machine can easily cut various shapes, including square, round, rectangular pipes, and other special-shaped tubes, offering versatility for different manufacturing needs.

Customizable pipe size: The machine can handle pipes with customizable diameters and lengths, with standard round pipe sizes ranging from Φ30 to 160mm and a maximum length of 6000mm, accommodating a wide range of pipe dimensions.

High cost performance: Offering low operational and maintenance costs, the machine provides excellent value for money. Its efficient design and minimal maintenance requirements reduce long-term expenses for businesses.

Simple and user-friendly operation: The cutting system is easy to operate, even for new users. It includes real-time feedback mechanisms to monitor the cutting process, ensuring smooth and efficient operations throughout the manufacturing cycle.

Round, oval, and square pipe cutting

The CNC Fiber Pipe Laser Cutting Machine is capable of cutting round, oval, square, and rectangular pipes, as well as other shaped pipes, offering flexibility for various pipe processing needs.

Variety of materials

It efficiently cuts different materials, including carbon steel, stainless steel, alloy steel, aluminum, and copper, making it suitable for a wide range of industrial applications.

Fitness equipment

This machine is commonly used in the production of fitness equipment, where precise pipe cutting is needed for items like frames, handlebars, and structural supports.

Oil pipelines

It plays a crucial role in the oil pipeline industry, providing high-precision cuts for pipes used in the transport and distribution of oil and gas.

Construction machinery

The machine is utilized in the construction machinery industry for cutting pipes that are part of heavy machinery, ensuring durability and precise dimensions for safety and functionality.

Automobile manufacturing

In the automotive industry, the machine cuts pipes for various components, such as exhaust systems, frames, and engine parts, contributing to production efficiency.

Household appliances

It is also used in household appliance production for cutting pipes and metal components, ensuring high-quality and accurately sized parts for product assembly.

General pipe processing

The machine is a valuable tool in any industry requiring precision pipe cutting, enhancing efficiency and quality in mass production and custom orders.

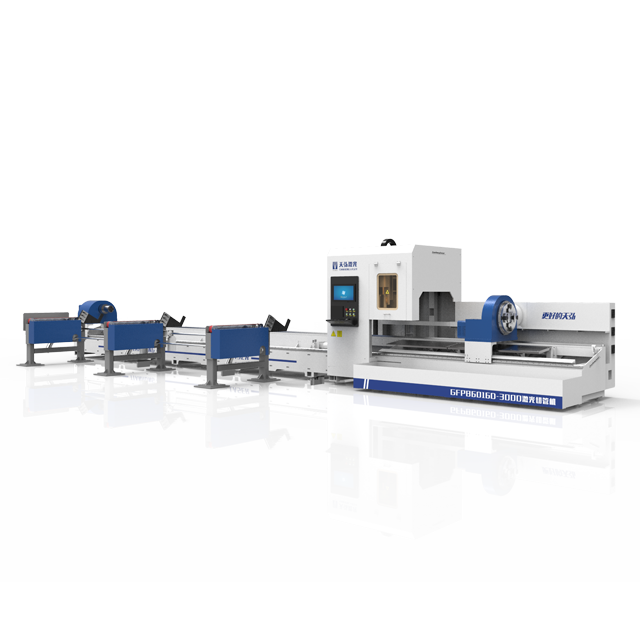

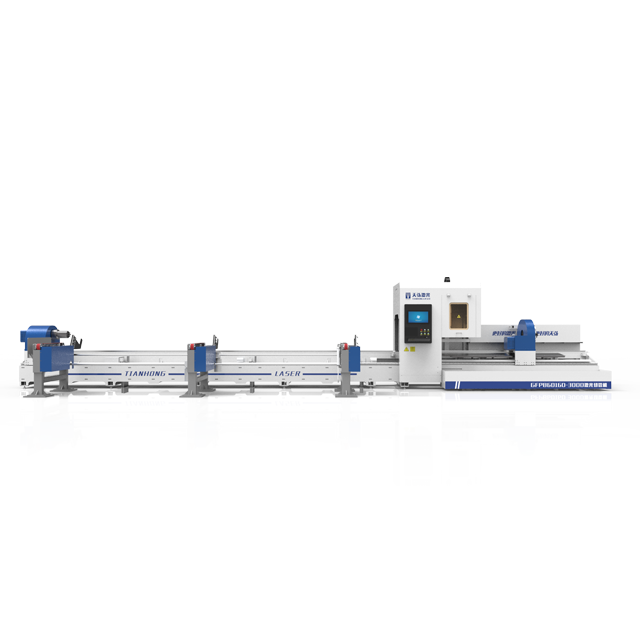

Model | GFPB6016D | GFPB6022D | GFPB6032D |

Laser power | 1000-4000W | 1000-4000W | 1000-4000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤400KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-70r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |

Model | GFPB6016D | GFPB6022D | GFPB6032D |

Laser power | 1000-4000W | 1000-4000W | 1000-4000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤400KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-70r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |