- All

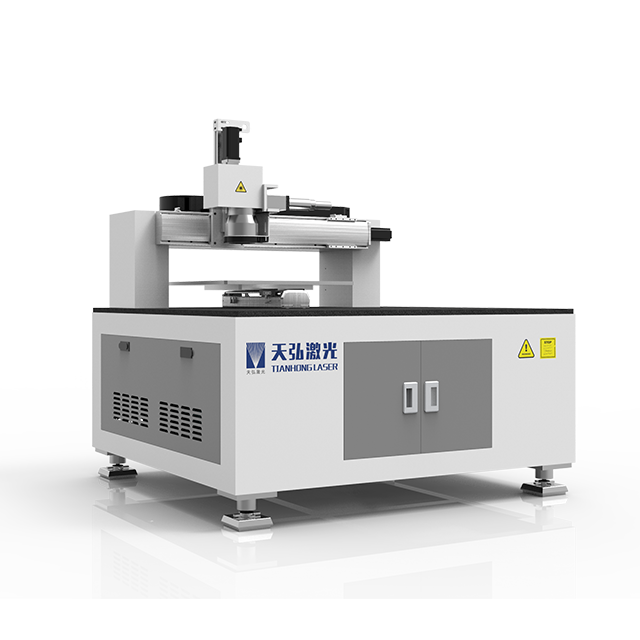

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Laser spot welding machines in automotive industry is a high-efficiency welding equipment integrating laser technology and intelligent process, designed for high-quality and high-precision laser welding applications. This laser spot welder is widely used in the microelectronics industry for circuit board welding, connecting sensors and fiber optic devices, as well as high-quality and high-speed spot welding of precision parts in machinery, automotive, aviation, aerospace and other fields.

Speed and Efficiency:Laser spot welding accelerates production with high-speed processing, making it ideal for automotive assembly lines. It enhances throughput, reducing cycle times and costs in high-volume manufacturing.

Precision and Versatility:The laser provides accurate, low-heat welds, joining a variety of materials, including dissimilar metals and thin sheets. This flexibility supports modern automotive design and lightweight construction.

Automation and Reduced Post-Weld Treatment:Laser welding integrates seamlessly with robotic systems for automated production, minimizing the need for manual labor. It also reduces post-weld distortion, cutting down on additional processing time and costs.

Strength, Durability, and Cost-Effectiveness:Laser spot welds are durable, handling stress and vibrations effectively. The process is cost-effective for mass production, offering reliable results and lower overall manufacturing expenses.

1.Welding of Roof Panels and Body Structures

Laser welding is highly effective for joining roof panels and body frames in vehicle manufacturing. The precision of the laser ensures strong, durable, and reliable welds, contributing to the vehicle’s structural integrity. It allows for seamless connections without affecting the appearance of the exterior, improving both strength and aesthetic quality. Additionally, it reduces the need for traditional welding processes, lowering production time and costs.

2.Joining of Dissimilar Metal Parts

Laser welding excels in joining dissimilar metals, such as steel and aluminum, which are commonly used in modern vehicle manufacturing for lightweight construction. The laser’s ability to bond these materials effectively helps reduce overall vehicle weight while maintaining strength and durability. This capability is critical for enhancing fuel efficiency and meeting industry standards for emissions reduction. Laser welding also ensures a clean, strong joint with minimal thermal distortion, improving the overall quality of the final product.

3.Welding of Thin-Walled Components

Thin-walled components, often used in automotive manufacturing for lightweight construction and intricate designs, are difficult to weld using traditional methods. Laser welding’s precise heat control allows for minimal heat input, reducing the risk of distortion or damage to these delicate materials. This results in high-quality, strong welds that maintain the structural integrity of the parts. Laser welding is perfect for joining small, thin components, such as brackets, frame supports, and other critical vehicle parts, ensuring both strength and efficiency.

Laser spot welding machines in automotive industry is a high-efficiency welding equipment integrating laser technology and intelligent process, designed for high-quality and high-precision laser welding applications. This laser spot welder is widely used in the microelectronics industry for circuit board welding, connecting sensors and fiber optic devices, as well as high-quality and high-speed spot welding of precision parts in machinery, automotive, aviation, aerospace and other fields.

Speed and Efficiency:Laser spot welding accelerates production with high-speed processing, making it ideal for automotive assembly lines. It enhances throughput, reducing cycle times and costs in high-volume manufacturing.

Precision and Versatility:The laser provides accurate, low-heat welds, joining a variety of materials, including dissimilar metals and thin sheets. This flexibility supports modern automotive design and lightweight construction.

Automation and Reduced Post-Weld Treatment:Laser welding integrates seamlessly with robotic systems for automated production, minimizing the need for manual labor. It also reduces post-weld distortion, cutting down on additional processing time and costs.

Strength, Durability, and Cost-Effectiveness:Laser spot welds are durable, handling stress and vibrations effectively. The process is cost-effective for mass production, offering reliable results and lower overall manufacturing expenses.

1.Welding of Roof Panels and Body Structures

Laser welding is highly effective for joining roof panels and body frames in vehicle manufacturing. The precision of the laser ensures strong, durable, and reliable welds, contributing to the vehicle’s structural integrity. It allows for seamless connections without affecting the appearance of the exterior, improving both strength and aesthetic quality. Additionally, it reduces the need for traditional welding processes, lowering production time and costs.

2.Joining of Dissimilar Metal Parts

Laser welding excels in joining dissimilar metals, such as steel and aluminum, which are commonly used in modern vehicle manufacturing for lightweight construction. The laser’s ability to bond these materials effectively helps reduce overall vehicle weight while maintaining strength and durability. This capability is critical for enhancing fuel efficiency and meeting industry standards for emissions reduction. Laser welding also ensures a clean, strong joint with minimal thermal distortion, improving the overall quality of the final product.

3.Welding of Thin-Walled Components

Thin-walled components, often used in automotive manufacturing for lightweight construction and intricate designs, are difficult to weld using traditional methods. Laser welding’s precise heat control allows for minimal heat input, reducing the risk of distortion or damage to these delicate materials. This results in high-quality, strong welds that maintain the structural integrity of the parts. Laser welding is perfect for joining small, thin components, such as brackets, frame supports, and other critical vehicle parts, ensuring both strength and efficiency.