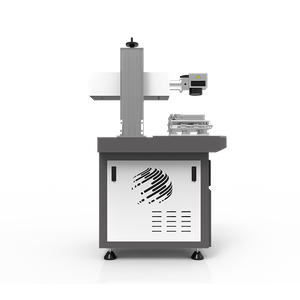

High-Quality Semiconductor Laser

The machine features a semiconductor laser imported from Germany, ensuring superior performance and reliability for precise welding in delicate parts.

Precise Temperature Control System

It utilizes an advanced temperature control system, maintaining stable operating conditions and ensuring consistent welding quality throughout the production process.

Accurate Wire Feeding System

The welder includes a precise wire feeding system, reducing the chances of misfeeds and ensuring uniform material flow for a clean, strong weld.

Maintenance-Free and Loss-Free Operation

With its high-quality components and advanced design, the system operates without the need for regular maintenance and avoids material wastage during the welding process.

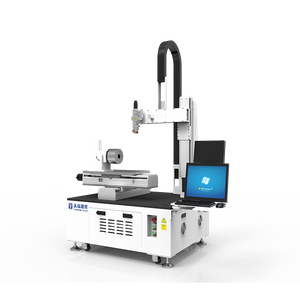

Four-Axis Three-Linkage CNC System

The machine is equipped with a sophisticated CNC system capable of four-axis control, allowing for highly flexible movement and positioning during the welding process.

Mitsubishi Control System Compatibility

It seamlessly integrates with the Mitsubishi control system, ensuring smooth communication and enhanced control over welding operations.

Ethernet Bus Control for Easy Programming

The system uses Ethernet bus control, simplifying programming and offering a user-friendly interface that enhances operational efficiency and ease of use.

Stable Performance

The combination of advanced control systems and precise hardware guarantees stable, reliable performance, even during long production runs, improving overall productivity.

Applications

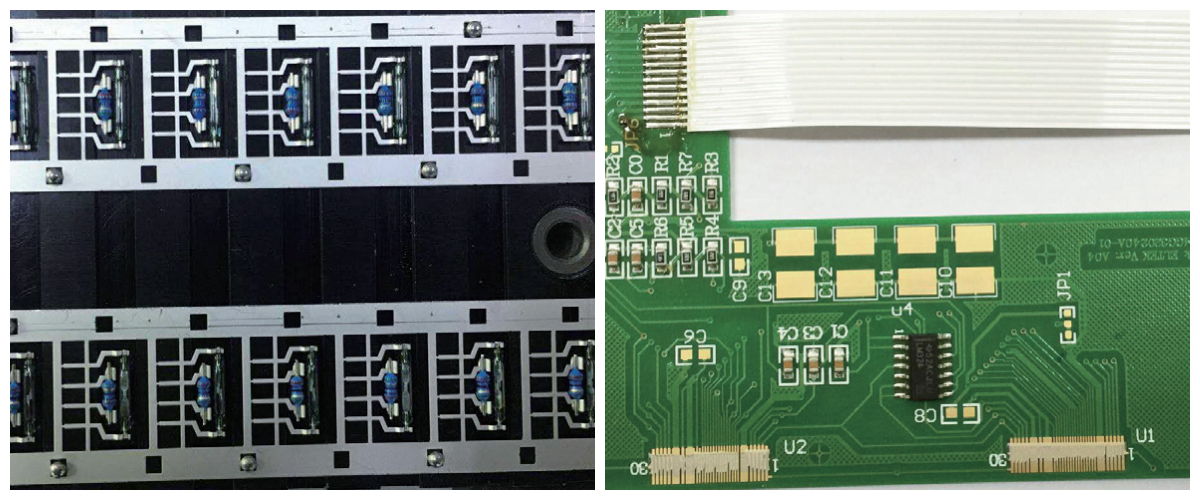

3C Microelectronics

The machine is used in the production of electronic components such as smartphones, computers, and consumer electronics, ensuring high-precision welding for small, delicate parts.

Automotive Microelectronics

It is widely used in the automotive industry for welding microelectronic components in vehicles, ensuring reliability and performance in critical automotive systems.

Optical Communications

The laser spot welder is ideal for the precision welding required in optical communication devices, providing strong, clean welds without damaging sensitive components.

Automobile Manufacturing

It plays a key role in welding parts in automotive production, from electrical systems to smaller precision components, supporting the manufacturing of reliable vehicle systems.

Aerospace Industry

The welder is used for delicate welding applications in aerospace components, where strength and precision are essential for safety and performance.

Electronics Industry

The machine is extensively used in electronics manufacturing, where it ensures precise welds for components such as circuit boards, connectors, and other small, complex parts.

Precision Instruments

In the production of precision instruments, the laser welder guarantees high-quality welds for fragile, small components that require exact joining without heat distortion.

Medical Devices

The welder is also employed in the medical device industry, providing precise welding for delicate medical components such as sensors and connectors, ensuring device functionality and safety.