- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

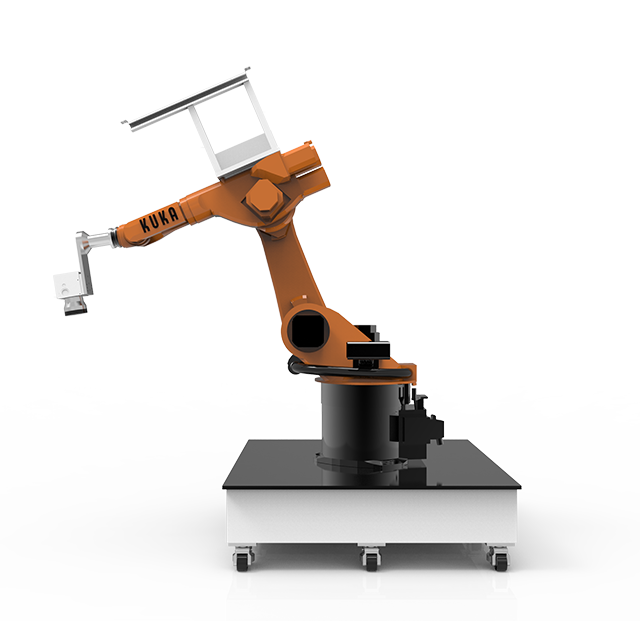

Automatic 6 Axis Robot Arm Fiber Laser Welding Machine is also called "three-dimensional laser welding machine", which adopts a parallel beam as the thermal power of heat treatment technology applications. Suitable for large space welding, robot intelligent operation, flexible and reliable, six-axis linkage, any space welding, not limited to plane welding.

» High precision and high accuracy. High-quality, high-performance harmonic reducers are used by this robotic welding machine to assure accuracy throughout repeated positioning running.

» Excellent sealing. Every axis is fully sealed, making it appropriate for environments with stringent sealing requirements that include dust, oil, hazardous gas liquid, and other elements.

» Enhanced safety precautions with multi-function protection to stop the manipulator welding equipment from overloading, overheating, or overvoltaging when using.

» Satisfy long-term mass production and customized extension axis is adopted for laser welding.

» It is inexpensive, environmentally friendly, simple to use and run. It is low energy consumption, practical and convenient, and capable of automatically finishing the full welding process while improving the quality of the final product.

Automatic 6 Axis Robot Arm Fiber Laser Welding Machine is specialized in the application of automotive hardware, medical equipment and other metal processing industry laser processing solutions, equipment in the design of the integrated structure of the machine, the use of multi-functional laser software control system, can effectively meet the different shapes of the welding, with flexible and diverse forms of application, suitable for a variety of different types of complex products, precision welding.

Automatic 6 Axis Robot Arm Fiber Laser Welding Machine is also called "three-dimensional laser welding machine", which adopts a parallel beam as the thermal power of heat treatment technology applications. Suitable for large space welding, robot intelligent operation, flexible and reliable, six-axis linkage, any space welding, not limited to plane welding.

» High precision and high accuracy. High-quality, high-performance harmonic reducers are used by this robotic welding machine to assure accuracy throughout repeated positioning running.

» Excellent sealing. Every axis is fully sealed, making it appropriate for environments with stringent sealing requirements that include dust, oil, hazardous gas liquid, and other elements.

» Enhanced safety precautions with multi-function protection to stop the manipulator welding equipment from overloading, overheating, or overvoltaging when using.

» Satisfy long-term mass production and customized extension axis is adopted for laser welding.

» It is inexpensive, environmentally friendly, simple to use and run. It is low energy consumption, practical and convenient, and capable of automatically finishing the full welding process while improving the quality of the final product.

Automatic 6 Axis Robot Arm Fiber Laser Welding Machine is specialized in the application of automotive hardware, medical equipment and other metal processing industry laser processing solutions, equipment in the design of the integrated structure of the machine, the use of multi-functional laser software control system, can effectively meet the different shapes of the welding, with flexible and diverse forms of application, suitable for a variety of different types of complex products, precision welding.