1000-6000W

6016-6032

carbon steel, stainless steel, alloy steel, aluminum, copper and other materials

| Availability: | |

|---|---|

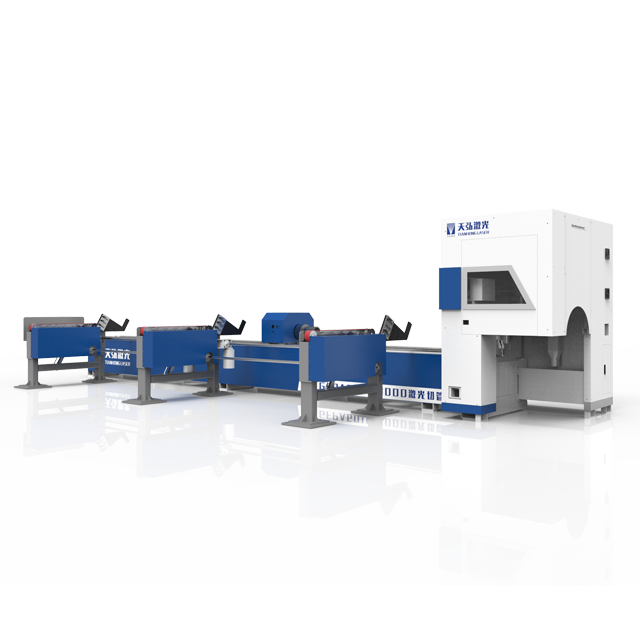

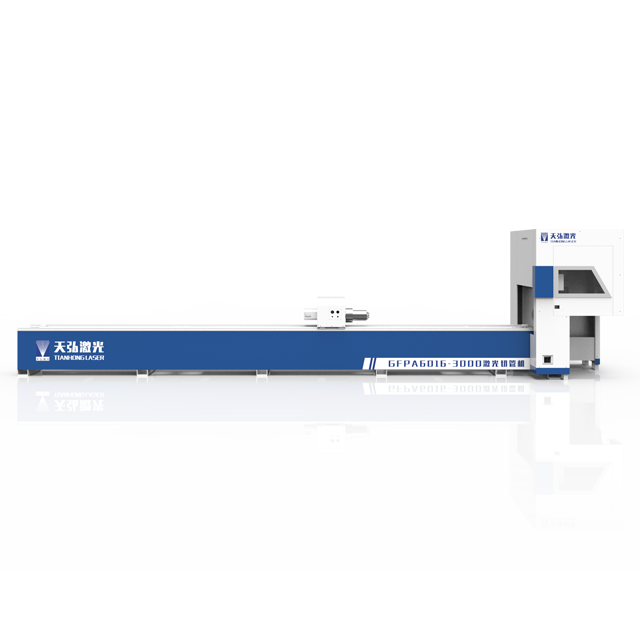

With the use of a dynamic focus system, a laser cutting head, and a well-known fiber laser source, the high efficiency metal tube laser cutting machine is able to quickly and precisely cut through a variety of metal materials. Because lasers are communicated via fiber, there is no need for maintenance or laser optical route adjustments, which significantly lowers the failure rate of the machines and increases their lifespan. Big format cutting space satisfies the needs of different metal processing types.

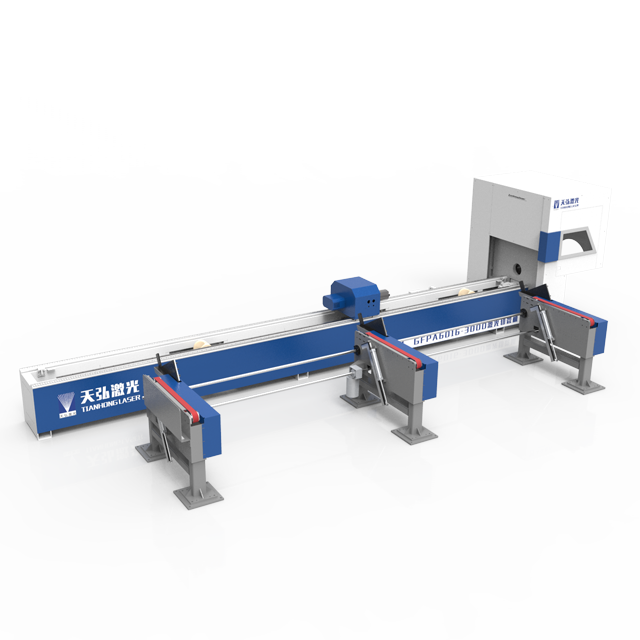

» The feeding area, unloading area and pipe cutting area are cleverly separated, which reduces the mutual interference between different areas and ensures a safe and stable production environment.

» The front chuck is equipped with double rows of roller claws to ensure processing accuracy;

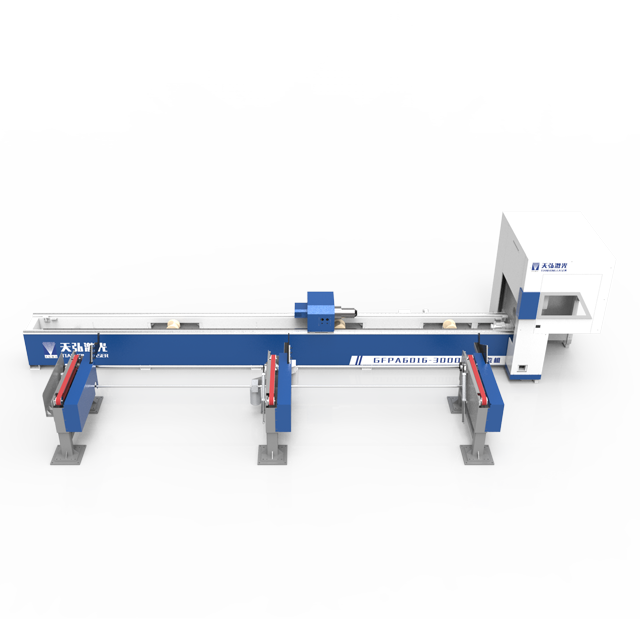

» The machine tool adopts a high-strength welded bed, professional mechanical analysis, good rigidity and high strength;

» The chuck is driven by a servo motor, equipped with high-precision gears, with high installation accuracy, large transmission torque, small transmission error, and good dynamic characteristics;

» The reducing wheel supports auxiliary cutting to ensure the processing accuracy of light and heavy pipes;

» A dust cover design is added to the Y-axis to prevent debris from splashing onto the transmission mechanism during processing, affecting processing accuracy and equipment safety;

» Two-way pneumatic chuck tube automatically locates the center, expands the transmission structure, improves operational stability, increases claws, and saves materials.

» The discharge area can be equipped with a discharge support device to prevent long materials from swinging and affecting accuracy.

This pipe cutting machine is suitable for a variety of coffin types, such as round tubes, oval tubes, square tubes, rectangular tubes, special-shaped tubes and other types of tubes, and is suitable for carbon steel, stainless steel, alloy steel, aluminum, copper and other metal materials; widely Used in various pipe processing industries, such as fitness equipment, oil pipelines, construction machinery, automobile manufacturing and household appliance manufacturing, etc.

With the use of a dynamic focus system, a laser cutting head, and a well-known fiber laser source, the high efficiency metal tube laser cutting machine is able to quickly and precisely cut through a variety of metal materials. Because lasers are communicated via fiber, there is no need for maintenance or laser optical route adjustments, which significantly lowers the failure rate of the machines and increases their lifespan. Big format cutting space satisfies the needs of different metal processing types.

» The feeding area, unloading area and pipe cutting area are cleverly separated, which reduces the mutual interference between different areas and ensures a safe and stable production environment.

» The front chuck is equipped with double rows of roller claws to ensure processing accuracy;

» The machine tool adopts a high-strength welded bed, professional mechanical analysis, good rigidity and high strength;

» The chuck is driven by a servo motor, equipped with high-precision gears, with high installation accuracy, large transmission torque, small transmission error, and good dynamic characteristics;

» The reducing wheel supports auxiliary cutting to ensure the processing accuracy of light and heavy pipes;

» A dust cover design is added to the Y-axis to prevent debris from splashing onto the transmission mechanism during processing, affecting processing accuracy and equipment safety;

» Two-way pneumatic chuck tube automatically locates the center, expands the transmission structure, improves operational stability, increases claws, and saves materials.

» The discharge area can be equipped with a discharge support device to prevent long materials from swinging and affecting accuracy.

This pipe cutting machine is suitable for a variety of coffin types, such as round tubes, oval tubes, square tubes, rectangular tubes, special-shaped tubes and other types of tubes, and is suitable for carbon steel, stainless steel, alloy steel, aluminum, copper and other metal materials; widely Used in various pipe processing industries, such as fitness equipment, oil pipelines, construction machinery, automobile manufacturing and household appliance manufacturing, etc.

Model | GFPA6016 | GFPA6022 | GFPA6032 |

Laser power | 1000-4000W | 1000-4000W | 1000-6000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤170KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-80r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |

Model | GFPA6016 | GFPA6022 | GFPA6032 |

Laser power | 1000-4000W | 1000-4000W | 1000-6000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤170KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-80r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |