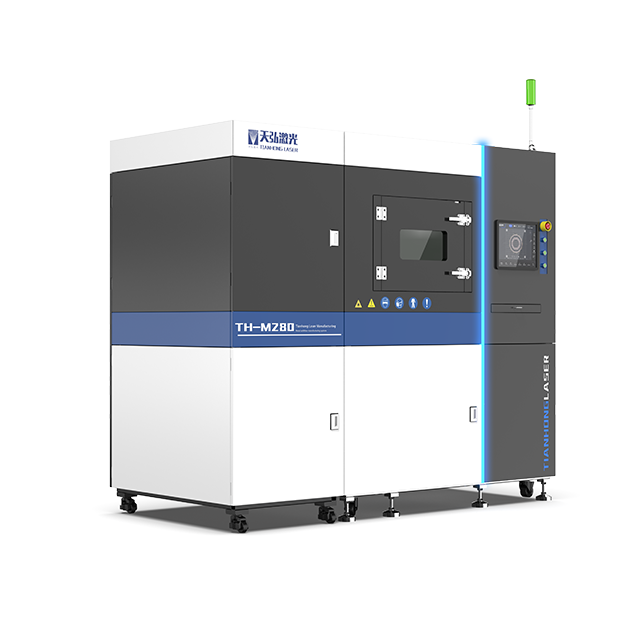

TH-M280

500W

286mmx286mmx450mm

Titanium alloys, aluminum alloys, high-temperature alloys, stainless steel, high-strength steel, die steel

| Availability: | |

|---|---|

TH-M280 Multi Material 3d Printer Metal combines the advantages of 3D printing technology and laser processing technology to realize high-precision and high-efficiency metal parts manufacturing. The whole printing process does not require molds, enabling the design and production of complex shapes and structures, greatly shortening the product development cycle and reducing production costs. Meanwhile, our products also have good processability and weldability, which is convenient for subsequent processing and assembly.

» Large molding size:

· Molding chamber size up to 286mmx286mmx380mm;

· Self-developed process software optimizes the scanning pathand shortens the processing time;

· Optional dual laser printing, compared with single laser printingefficiencyincreased by about 70%;

» High accuracy and performance:

· Metal printing density >99.5%, mechanical propertyfluctuation <5%;

· Self-designed optical system, excellent wind field designto ensure high molding accuracy and molded partsperformance;

» Full quality assurance:

· Real-time display of equipment information during the printingprocess, automatic generation ofelectronic version of the printreport after the completion of printing, process parameters canbe traced;

· Automatic and detailed processing log of the system records thelayer of parts in the printing process, such as part temperature,chamber pressure, oxygen content, molding cylinder position,material cylinder position, powder spreading car position,processing time, etc.are recorded.

» Safe and reliable

· Good chamber airtightness, constant chamber pressure<100ppm oxygen content during printing, smallfluctuation;

· Real-time monitoring of working environment and gassource status, safe and reliable.

In terms of application fields, Multi Material 3d Printers Metal are widely used in aerospace, automobile manufacturing, medical devices, mold manufacturing and other industries. For example, in the field of aerospace, our products can be used to manufacture engine parts, aviation structural parts, etc.; in the field of automobile manufacturing, they can be used to manufacture engine blocks, chassis parts, etc.; in the field of medical devices, they can be used to manufacture implantable medical devices and surgical instruments, etc.

TH-M280 Multi Material 3d Printer Metal combines the advantages of 3D printing technology and laser processing technology to realize high-precision and high-efficiency metal parts manufacturing. The whole printing process does not require molds, enabling the design and production of complex shapes and structures, greatly shortening the product development cycle and reducing production costs. Meanwhile, our products also have good processability and weldability, which is convenient for subsequent processing and assembly.

» Large molding size:

· Molding chamber size up to 286mmx286mmx380mm;

· Self-developed process software optimizes the scanning pathand shortens the processing time;

· Optional dual laser printing, compared with single laser printingefficiencyincreased by about 70%;

» High accuracy and performance:

· Metal printing density >99.5%, mechanical propertyfluctuation <5%;

· Self-designed optical system, excellent wind field designto ensure high molding accuracy and molded partsperformance;

» Full quality assurance:

· Real-time display of equipment information during the printingprocess, automatic generation ofelectronic version of the printreport after the completion of printing, process parameters canbe traced;

· Automatic and detailed processing log of the system records thelayer of parts in the printing process, such as part temperature,chamber pressure, oxygen content, molding cylinder position,material cylinder position, powder spreading car position,processing time, etc.are recorded.

» Safe and reliable

· Good chamber airtightness, constant chamber pressure<100ppm oxygen content during printing, smallfluctuation;

· Real-time monitoring of working environment and gassource status, safe and reliable.

In terms of application fields, Multi Material 3d Printers Metal are widely used in aerospace, automobile manufacturing, medical devices, mold manufacturing and other industries. For example, in the field of aerospace, our products can be used to manufacture engine parts, aviation structural parts, etc.; in the field of automobile manufacturing, they can be used to manufacture engine blocks, chassis parts, etc.; in the field of medical devices, they can be used to manufacture implantable medical devices and surgical instruments, etc.

Model | TH-M280 |

Dimension | L(3145)xW(1270)xH(2500) mm |

Forming cylinder size | 286mmx286mmx450mm |

Scanning speed | 7m/s |

Light spot diameter | 70~120μm |

Light source | 500W |

Powder layering thickness | 20~120μm |

Forming speed | Max 35cm3 /h |

Applicable material | Titanium alloys, aluminum alloys,high-temperature alloys, stainless steelhigh-strength steel, die steel |

Preheating temperature | 20~200°C |

Chamber oxygen level | ≤100ppm |

Protective gas | Nitrogen/Argon |

Data format | STL file or other conversion format |

Complementary software | TH-3Dprint; Tianhong self-developed |

| Electrical consumption | 380V, 20.1KW |

| Weight | 2.1T |

Model | TH-M280 |

Dimension | L(3145)xW(1270)xH(2500) mm |

Forming cylinder size | 286mmx286mmx450mm |

Scanning speed | 7m/s |

Light spot diameter | 70~120μm |

Light source | 500W |

Powder layering thickness | 20~120μm |

Forming speed | Max 35cm3 /h |

Applicable material | Titanium alloys, aluminum alloys,high-temperature alloys, stainless steelhigh-strength steel, die steel |

Preheating temperature | 20~200°C |

Chamber oxygen level | ≤100ppm |

Protective gas | Nitrogen/Argon |

Data format | STL file or other conversion format |

Complementary software | TH-3Dprint; Tianhong self-developed |

| Electrical consumption | 380V, 20.1KW |

| Weight | 2.1T |

Sample

Sample

Sample

Sample

Sample

Sample

Sample

Sample