6000W-30000W

6000*2500mm, 8000*2500mm, 12000*2500mm

Carbon steel plates, stainlesssteel plates, copper plates, aluminum alloy plates

| Availability: | |

|---|---|

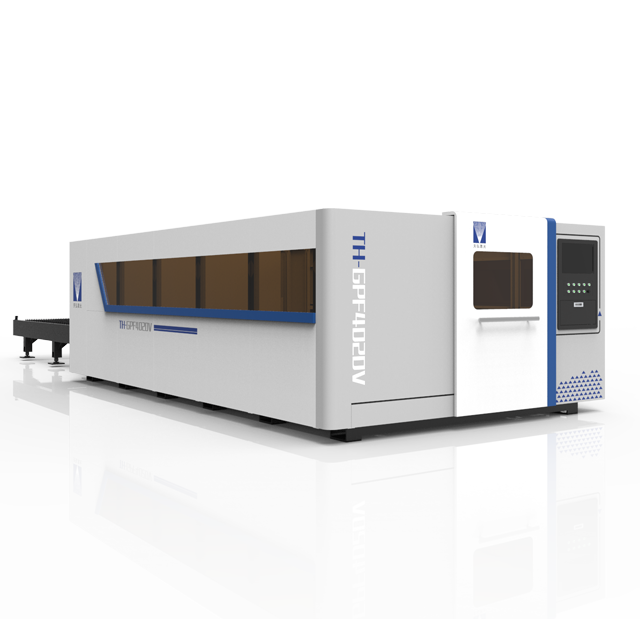

High power cutting machine is capable of cutting thick metal plates with high speed, high precision, smooth cutting surface and high stability to meet the processing needs of thick metal plates in various industries.At present, the laser cutting machine can be completely applied in the field of metal processing, whether it is stainless steel, carbon steel and other common metal materials, or difficult to deal with high anti-materials such as aluminum, fiber laser cutting machine can be easily dealt with, and with the continuous improvement of the power of the laser cutting machine, can be processed by the thickness of the metal plate is also with the increase day by day.

» It adopts multi-module output and is equipped with thermal redundancy technology to realize ultra-high power and ultra-high stability. It can cut all kinds of metal thick plates including copper and aluminum under harsh working conditions. Contour reflective materials;

» After the scattered light is reflected, suppressed and shielded, the scattered light is recycled and reused twice and three times, thus enhancing the available laser beam energy;

» The perforation time of thick metal plates is greatly reduced, cutting speed is greatly increased, and the cutting section is brighter and more delicate. The overall efficiency is increased by 10-15%;

» The cutting system can automatically sense and match the cutting environment when cutting plates of different thicknesses and materials, adjust the cutting parameters, and realize intelligent cutting data compensation for plates of special materials;

» Adopting built-in ventilation duct system. One is to avoid the spread of smoke and dust in the production process, not only energy saving and environmental protection, to ensure safe production, but also effectively extend the service life of the machine parts; the overall operation of the equipment is more stable

High-power laser cutting machines are mainly used for sheet metal processing in the engineering machinery industry, generally using fiber laser cutting machines. The current cutting applications of laser cutting machines in the construction machinery industry mainly include slender workpieces, porous plates, sheet metal process leaving marks, sheet metal sample making and drilling sample making.

High power cutting machine is capable of cutting thick metal plates with high speed, high precision, smooth cutting surface and high stability to meet the processing needs of thick metal plates in various industries.At present, the laser cutting machine can be completely applied in the field of metal processing, whether it is stainless steel, carbon steel and other common metal materials, or difficult to deal with high anti-materials such as aluminum, fiber laser cutting machine can be easily dealt with, and with the continuous improvement of the power of the laser cutting machine, can be processed by the thickness of the metal plate is also with the increase day by day.

» It adopts multi-module output and is equipped with thermal redundancy technology to realize ultra-high power and ultra-high stability. It can cut all kinds of metal thick plates including copper and aluminum under harsh working conditions. Contour reflective materials;

» After the scattered light is reflected, suppressed and shielded, the scattered light is recycled and reused twice and three times, thus enhancing the available laser beam energy;

» The perforation time of thick metal plates is greatly reduced, cutting speed is greatly increased, and the cutting section is brighter and more delicate. The overall efficiency is increased by 10-15%;

» The cutting system can automatically sense and match the cutting environment when cutting plates of different thicknesses and materials, adjust the cutting parameters, and realize intelligent cutting data compensation for plates of special materials;

» Adopting built-in ventilation duct system. One is to avoid the spread of smoke and dust in the production process, not only energy saving and environmental protection, to ensure safe production, but also effectively extend the service life of the machine parts; the overall operation of the equipment is more stable

High-power laser cutting machines are mainly used for sheet metal processing in the engineering machinery industry, generally using fiber laser cutting machines. The current cutting applications of laser cutting machines in the construction machinery industry mainly include slender workpieces, porous plates, sheet metal process leaving marks, sheet metal sample making and drilling sample making.

Model | TH-GPF6025 | TH-GPF8025 | TH-GPF12025 |

Laser power | 6000W-30000W | 6000W-30000W | 12000W-30000W |

Z-axis path | 350mm | 350mm | 350mm |

Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

Repetition positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

Processing format | 6000*2500mm | 8000*2500mm | 12000*2500mm |

Model | TH-GPF6025 | TH-GPF8025 | TH-GPF12025 |

Laser power | 6000W-30000W | 6000W-30000W | 12000W-30000W |

Z-axis path | 350mm | 350mm | 350mm |

Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

Repetition positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

Processing format | 6000*2500mm | 8000*2500mm | 12000*2500mm |