- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

100-500W

Aluminum, carbon steel, stainless steel, galvanized sheets

| Availability: | |

|---|---|

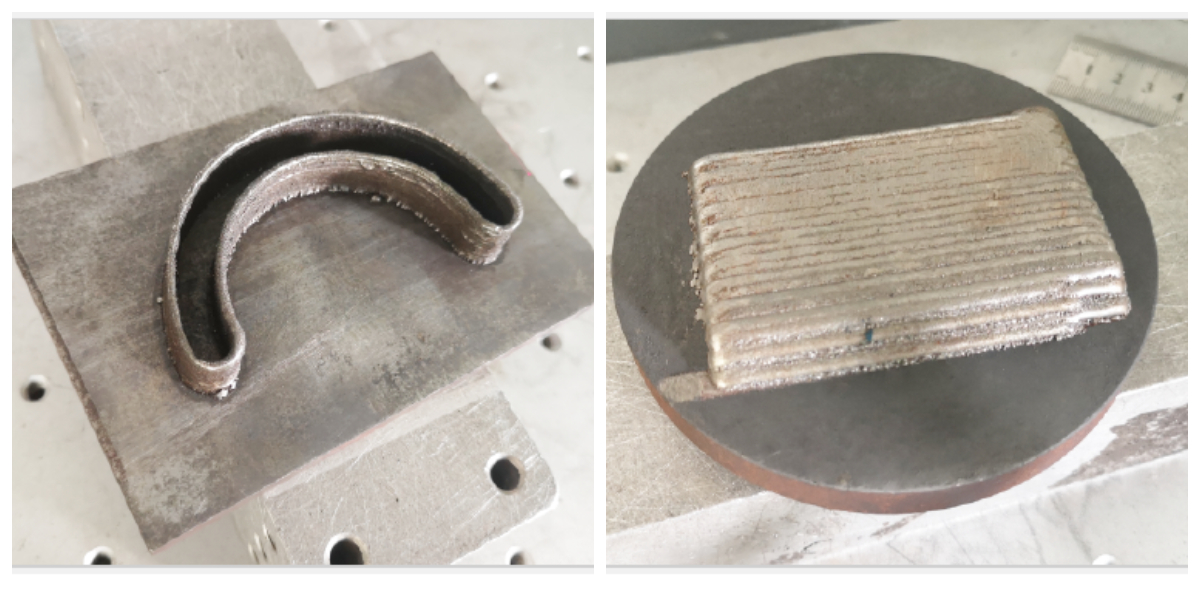

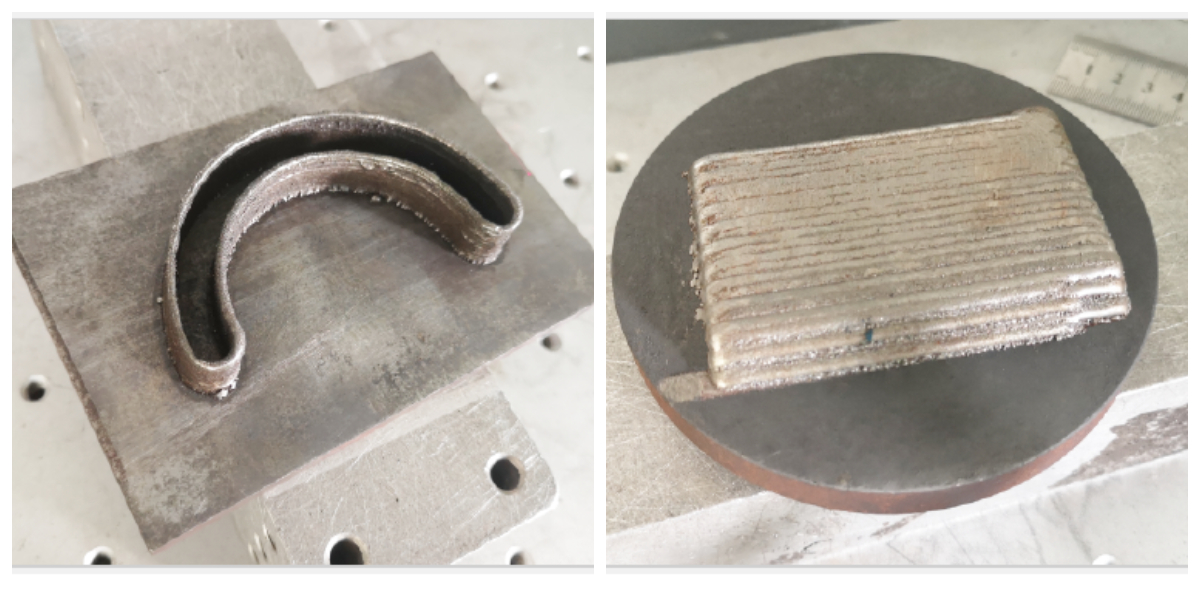

Portable Laser Cleaning Machine is a use of high-energy laser beam to remove the surface of the workpiece rust, oil, etc. cleaning machine, laser cleaning machine using high-frequency high-energy laser irradiation of the surface of the workpiece, the coating layer can be instantly absorbed by the focused laser energy, so that the surface of the oil, rust, or the coating occurs in an instant evaporation or peeling, high-speed and effective removal of surface adhesions or surface coatings, and the action of the laser treatment of a very short period of time in the appropriate parameters Under the appropriate parameters will not harm the metal substrate.Laser cleaning machine can not only clean organic pollutants, but also capable of cleaning inorganic substances, including metal rust, metal particles, dust, rapid paint removal, oil removal.

» Laser cleaning is a "green" cleaning methods, do not need to use any chemicals and cleaning fluids, cleaning down the waste is basically solid powder, can easily solve the environmental pollution problems caused by chemical cleaning;

» Traditional cleaning methods are often contact cleaning, cleaning the surface of the object has a mechanical force, damage to the surface of the object or cleaning medium attached to the surface of the object to be cleaned, can not be removed, resulting in secondary pollution, the laser cleaning of the non-abrasive and non-contact nature of these problems to be solved;

» The laser can be transmitted through the fiber optic transmission, handheld laser cleaning gun head lightweight, 10 meters long distance, easy to achieve long-distance operation, can clean the traditional method is not easy to reach the parts and angles;

» Laser cleaning can remove various types of pollutants on the surface of various materials, to achieve the cleanliness that cannot be achieved by conventional cleaning. And it can also selectively clean the pollutants on the surface of the material without damaging the surface of the material;

» Laser cleaning is highly efficient and saves time;

Portable Laser Cleaning Machine is widely used in mold cleaning, weaponry cleaning, metal welding pretreatment cleaning, aircraft old paint cleaning, building facade cleaning, electronics industry cleaning, cultural relics cleaning, rock cleaning, exterior surfaces of buildings cleaning, nuclear power reactors pipe cleaning, oxide treatment cleaning, paint removal and rust removal during ship production and maintenance.

Portable Laser Cleaning Machine is a use of high-energy laser beam to remove the surface of the workpiece rust, oil, etc. cleaning machine, laser cleaning machine using high-frequency high-energy laser irradiation of the surface of the workpiece, the coating layer can be instantly absorbed by the focused laser energy, so that the surface of the oil, rust, or the coating occurs in an instant evaporation or peeling, high-speed and effective removal of surface adhesions or surface coatings, and the action of the laser treatment of a very short period of time in the appropriate parameters Under the appropriate parameters will not harm the metal substrate.Laser cleaning machine can not only clean organic pollutants, but also capable of cleaning inorganic substances, including metal rust, metal particles, dust, rapid paint removal, oil removal.

» Laser cleaning is a "green" cleaning methods, do not need to use any chemicals and cleaning fluids, cleaning down the waste is basically solid powder, can easily solve the environmental pollution problems caused by chemical cleaning;

» Traditional cleaning methods are often contact cleaning, cleaning the surface of the object has a mechanical force, damage to the surface of the object or cleaning medium attached to the surface of the object to be cleaned, can not be removed, resulting in secondary pollution, the laser cleaning of the non-abrasive and non-contact nature of these problems to be solved;

» The laser can be transmitted through the fiber optic transmission, handheld laser cleaning gun head lightweight, 10 meters long distance, easy to achieve long-distance operation, can clean the traditional method is not easy to reach the parts and angles;

» Laser cleaning can remove various types of pollutants on the surface of various materials, to achieve the cleanliness that cannot be achieved by conventional cleaning. And it can also selectively clean the pollutants on the surface of the material without damaging the surface of the material;

» Laser cleaning is highly efficient and saves time;

Portable Laser Cleaning Machine is widely used in mold cleaning, weaponry cleaning, metal welding pretreatment cleaning, aircraft old paint cleaning, building facade cleaning, electronics industry cleaning, cultural relics cleaning, rock cleaning, exterior surfaces of buildings cleaning, nuclear power reactors pipe cleaning, oxide treatment cleaning, paint removal and rust removal during ship production and maintenance.

| Model | TH-LC-100D-A | TH-LC-200D-A | TH-LC-300D-A | TH-LC-500D-A |

| Laser power | 100W | 200W | 300W | 500W |

| Laser type | Fiber Laser | |||

| Wavelength | 1064nm | |||

| Cooling method | Air cooling/ water cooling | |||

| Water temperature | 18-25℃ | |||

| Cabinet dimension | 575x400x500mm | 610x500x700mm | 640x540x730mm | 850x830x960mm |

| Machine weight | 39.5kg | 52kg | 54kg | 120kg |

| Power consumption | 800W | 1400W | 1600W | 1800W |

| Focus depth | 3mm | 5mm | 10mm | 15mm |

| Scanning width | 2-50mm | |||

| Auxiliary gas | Compressed air / nitrogen | |||

| Air pressure | 0.5-0.8Mpa | |||

| Working environment | 5-40℃ | |||

| Model | TH-LC-100D-A | TH-LC-200D-A | TH-LC-300D-A | TH-LC-500D-A |

| Laser power | 100W | 200W | 300W | 500W |

| Laser type | Fiber Laser | |||

| Wavelength | 1064nm | |||

| Cooling method | Air cooling/ water cooling | |||

| Water temperature | 18-25℃ | |||

| Cabinet dimension | 575x400x500mm | 610x500x700mm | 640x540x730mm | 850x830x960mm |

| Machine weight | 39.5kg | 52kg | 54kg | 120kg |

| Power consumption | 800W | 1400W | 1600W | 1800W |

| Focus depth | 3mm | 5mm | 10mm | 15mm |

| Scanning width | 2-50mm | |||

| Auxiliary gas | Compressed air / nitrogen | |||

| Air pressure | 0.5-0.8Mpa | |||

| Working environment | 5-40℃ | |||