- All

- Product Name

- Product Keyword

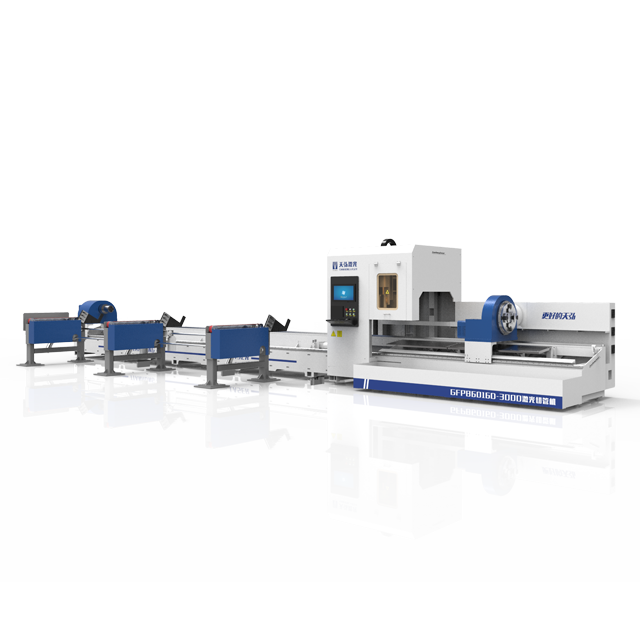

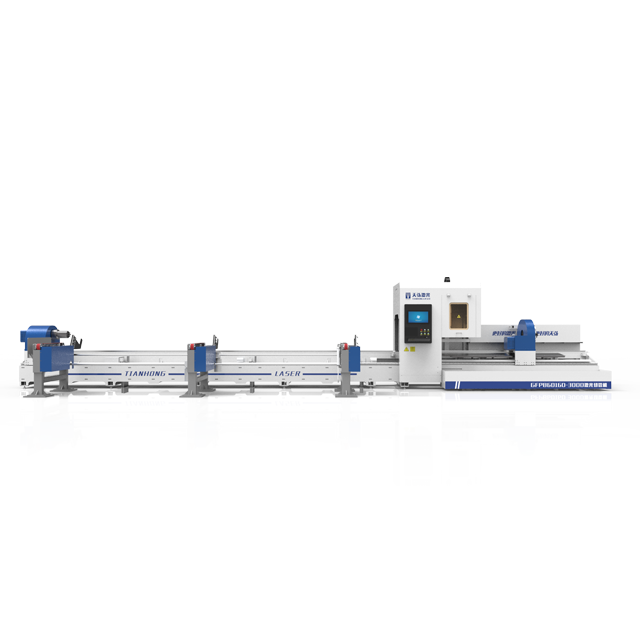

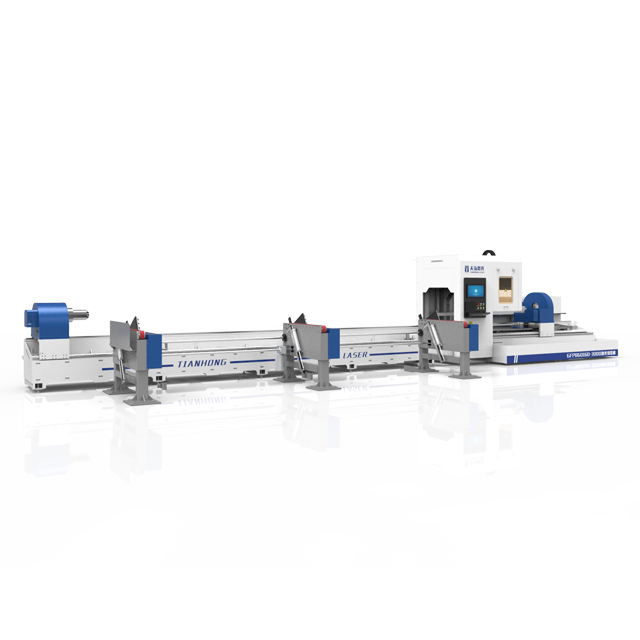

- Product Model

- Product Summary

- Product Description

- Multi Field Search

1000W-4000W

6016-6032

carbon steel, stainless steel, alloy steel, aluminum, copper, etc

| Availability: | |

|---|---|

The innovative self-centering four-jaw chuck technology is used by high quality fiber pipe laser cutting machine to eliminate the rope pendulum effect and increase the precision of cutting thin tubes. Two chucks have automatic loading and unloading structures installed, which reduces labor costs and boosts output effectiveness.

» Automatic feeding: After placing the entire bundle of pipes into the feeding device, intelligent material distribution and feeding are realized, and seamlessly connected with the laser pipe cutting machine;

» Can meet the cutting and punching needs of various types of pipes, solving the problem that traditional processing technology requires multiple processes and expensive labor;

» Intelligent CNC chuck. It can realize automatic centering and precise clamping of pipes, and the front and rear center clamp design ensures that the pipes are clamped without deformation;

» The servo follow-up support system can realize the horizontal transportation of pipes, ensuring the smooth operation of the equipment and ensuring processing accuracy;

» Bus control system. Rich process database, easy to operate and powerful, can be developed in depth according to different customer needs;

» Middle and front chucks avoid cutting, with a minimum tail length of up to 70mm;

» The machine tool adopts a high-strength welded bed, which has good rigidity and high strength;

» Subsequent support for auxiliary cutting ensures the processing accuracy of light and heavy pipes;

» Automatic unloading: The finished product automatically falls into the storage bin, and double support bearings assist in supporting the extra-long pipe.

This pipe cutting machine is widely used in various pipe processing industries, such as fitness equipment, oil pipelines, construction machinery, automobile and household appliance manufacturing, etc. It is suitable for a variety of coffin types, including round, oval, square, rectangular, and special-shaped tubes. It is also suitable for carbon steel, stainless steel, alloy steel, aluminum, copper, and other metal materials.

The innovative self-centering four-jaw chuck technology is used by high quality fiber pipe laser cutting machine to eliminate the rope pendulum effect and increase the precision of cutting thin tubes. Two chucks have automatic loading and unloading structures installed, which reduces labor costs and boosts output effectiveness.

» Automatic feeding: After placing the entire bundle of pipes into the feeding device, intelligent material distribution and feeding are realized, and seamlessly connected with the laser pipe cutting machine;

» Can meet the cutting and punching needs of various types of pipes, solving the problem that traditional processing technology requires multiple processes and expensive labor;

» Intelligent CNC chuck. It can realize automatic centering and precise clamping of pipes, and the front and rear center clamp design ensures that the pipes are clamped without deformation;

» The servo follow-up support system can realize the horizontal transportation of pipes, ensuring the smooth operation of the equipment and ensuring processing accuracy;

» Bus control system. Rich process database, easy to operate and powerful, can be developed in depth according to different customer needs;

» Middle and front chucks avoid cutting, with a minimum tail length of up to 70mm;

» The machine tool adopts a high-strength welded bed, which has good rigidity and high strength;

» Subsequent support for auxiliary cutting ensures the processing accuracy of light and heavy pipes;

» Automatic unloading: The finished product automatically falls into the storage bin, and double support bearings assist in supporting the extra-long pipe.

This pipe cutting machine is widely used in various pipe processing industries, such as fitness equipment, oil pipelines, construction machinery, automobile and household appliance manufacturing, etc. It is suitable for a variety of coffin types, including round, oval, square, rectangular, and special-shaped tubes. It is also suitable for carbon steel, stainless steel, alloy steel, aluminum, copper, and other metal materials.

Model | GFPB6016D | GFPB6022D | GFPB6032D |

Laser power | 1000-4000W | 1000-4000W | 1000-4000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤400KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-70r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |

Model | GFPB6016D | GFPB6022D | GFPB6032D |

Laser power | 1000-4000W | 1000-4000W | 1000-4000W |

Max. Tube clamping weight | ≤120KG | ≤170KG | ≤400KG |

X-axis and Y-axis positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

X-axis and Y-axis repetition positioning accuracy | ±0.03mm/1000mm | ±0.03mm/1000mm | ±0.03mm/1000mm |

Chuck rotating speed | 0-80r/min | 0-70r/min | 0-60r/min |

Clamping tube range | Φ10-Φ160,□10-□110 | Φ10-Φ220,□10-□155 | Φ10-Φ320,□10-□225 |