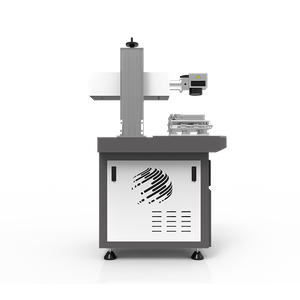

Non-contact processing

The CO2 laser marking machine works without touching the material, making it ideal for marking on both regular and irregular surfaces, ensuring precise and fine marks without any physical contact.

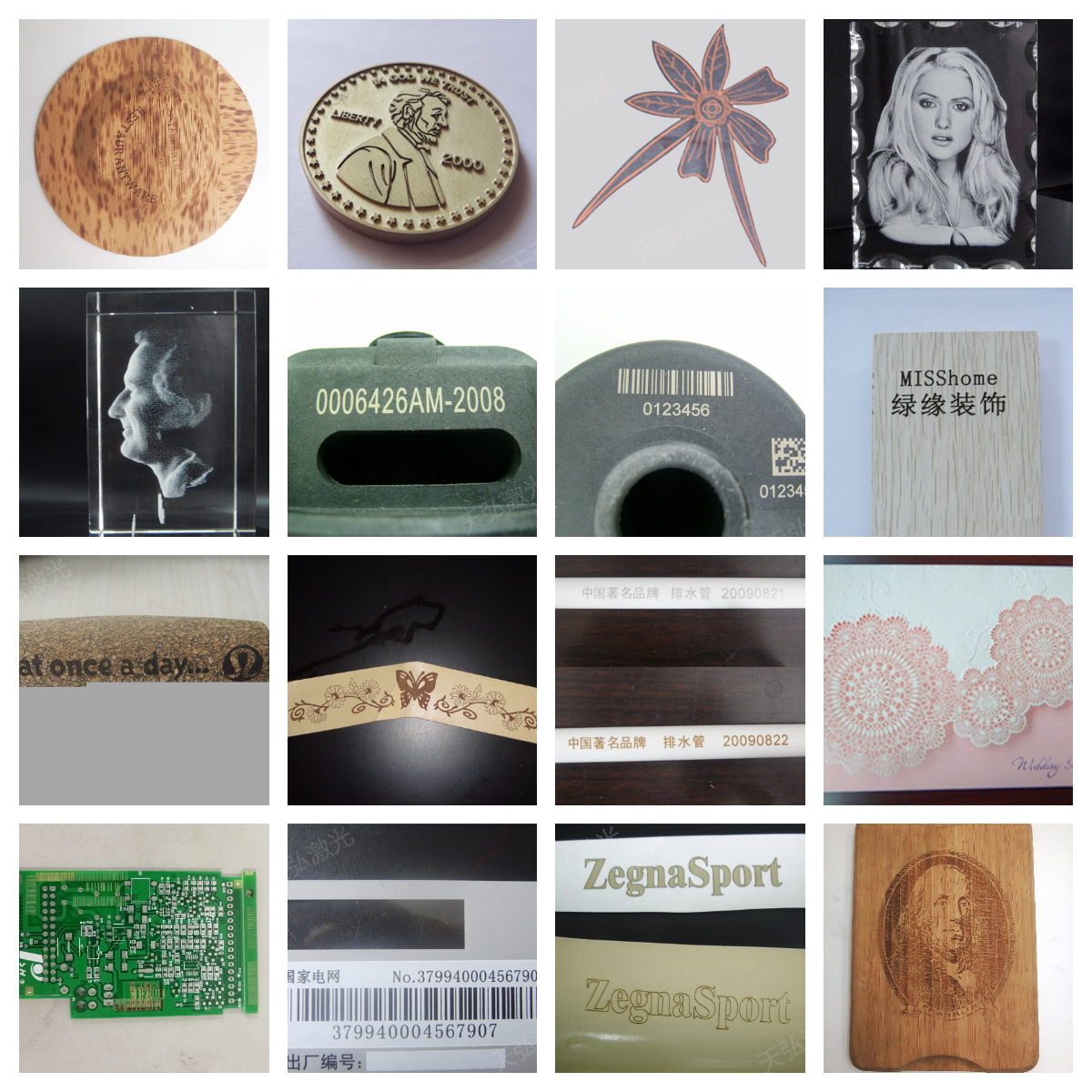

Wide surface applicability

This machine can mark and engrave graphics on a wide range of materials, including most non-metallic surfaces and certain metals, providing versatility for various industries.

Low running costs

With high-speed marking and minimal consumables required, this machine offers a cost-effective solution, reducing operating expenses while maintaining efficiency in production.

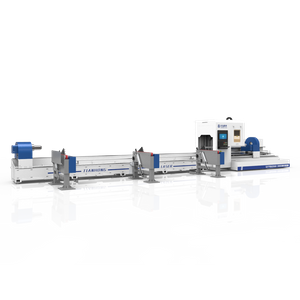

Assembly line integration

The machine can be easily integrated into an assembly line, working alongside other equipment to improve the overall automation of the production process, increasing productivity.

Clear and permanent marking

The CO2 laser ensures that the marks are clear, permanent, and resistant to erasure, making them ideal for applications requiring anti-counterfeiting measures and long-lasting identification.

Efficient and easy operation

The machine offers simple operation and high efficiency. It can be adjusted to meet different marking depth and color requirements, providing flexible solutions for various needs.

Non-contact mode

The non-contact nature of the machine prevents any potential damage or contamination that traditional marking methods might cause, preserving the integrity and cleanliness of glass products.

Long service life

The machine’s durable design ensures a long operational lifespan, making it a reliable and sustainable investment for continuous use in production lines without frequent replacements.

Environmental friendly

The process generates no pollution, making it an eco-friendly option for marking and engraving, contributing to a cleaner production environment.